Joint development of a process for 200,000 tons per year

The world’s leading provider of renewable diesel, renewable jet fuel, and an expert in delivering drop-in renewable chemical solutions, Neste, and the world’s leading distributor and recycler of polymers, Ravago, are joining forces to develop chemical recycling of plastic waste with the aim to reach significant industrial scale. Neste and Ravago have set a joint target to reach an annual capacity to process over 200,000 tons of waste plastic.

The world’s leading provider of renewable diesel, renewable jet fuel, and an expert in delivering drop-in renewable chemical solutions, Neste, and the world’s leading distributor and recycler of polymers, Ravago, are joining forces to develop chemical recycling of plastic waste with the aim to reach significant industrial scale. Neste and Ravago have set a joint target to reach an annual capacity to process over 200,000 tons of waste plastic.

Through collaborating in chemical recycling, Neste and Ravago wish to accelerate circularity of materials and improve resource-efficiency in the petrochemical industry. The two companies also want to provide more sustainable alternatives to primary fossil feedstock. Chemical recycling of plastic waste will enable the petrochemical industry to meet its recycling targets and develop a more sustainable, climate-friendlier offering.

“Ravago’s geographical reach and expertise in plastics recycling together with Neste’s track record in upgrading challenging refinery feedstock provide an excellent foundation for demonstrating and scaling up chemical recycling with speed. Collaboration also brings Neste closer to having the necessary partnerships and infrastructure to meet our Plastics Pledge target. Our aim is to process annually more than one million tons of plastic waste from 2030 onwards. With this, we could contribute to increasing the annual recycling rate of post-consumer plastic waste by 25 to 30% from the current level in Europe,” says Mercedes Alonso, Executive Vice President, Renewable Polymers and Chemicals at Neste.

“At Ravago, we carry the waste issue at heart. Our company has been mechanically recycling polymers for nearly 60 years, however chemical recycling should be part of a sustainable solution that our society requires today to address the growing need for valorising consumer waste. We are proud and energised to establish this partnership with Neste, who is the leading company in the field of renewables, as it provides a solid foundation to enable the different nascent technologies to mature and the broader industry to take off. We want to give a definitive answer to plastic waste issue,” adds Theo Roussis, CEO of Ravago.

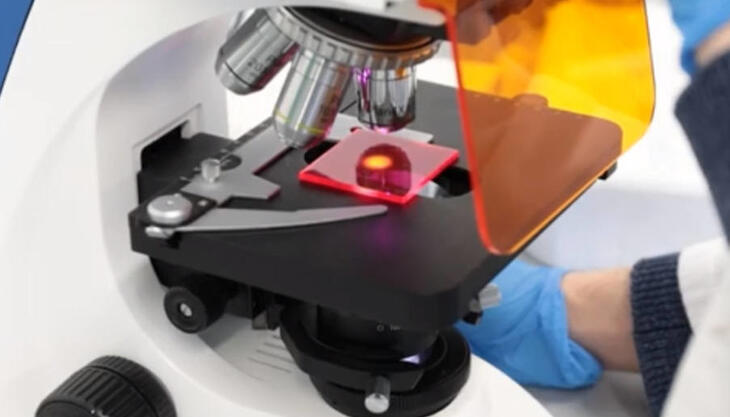

Chemical recycling will enable the companies to upgrade even colored and mixed plastic packaging waste into high-quality raw material for the production of new plastics, chemicals and fuels. Unlike mechanically recycled plastics, chemical recycling enables waste plastic to be used as raw material even in the most sensitive applications, such as in primary food packaging as well as pharmaceutical and healthcare applications.