New reference for predictive simulation with glass-fibre reinforced polyamide 6 compounds

By Gilles Robert, Material Expert at DOMO

Application performance simulation performed with MMI by DOMO SERVICE HUB

Predictive simulation can be a strong tool to accelerate the time-to-market of new products by minimising the number of development and prototyping cycles. Based on the experience gained using Multi-scale modelling, Mechanical calculation and Injection moulding simulation (MMI) with glass-filled TECHNYL polyamide 6.6 (PA 66) resins, DOMO now offers MMI TECHNYL Design support for its range of PA 6 based TECHNYL C compounds.

The integrated MMI technology runs on Digimat software from e-Xstream engineering SA. As a structural modelling platform, Digimat allows design engineers to analyse and predict the mechanical, thermal and electrical performance of plastics in final parts. It uses Digimat-MX, a detailed material exchange database that provides accurate material models for simulation based on MMI material cards.

DOMO’s MMI material cards for PA 66 are widely recognised in the industry as a reference for accurate simulation and robust finite-element analysis. New MMI cards for TECHNYL C extend these capabilities to glass-filled PA 6, helping OEMs and part suppliers take their innovative PA 6 application solutions to the next level. The TECHNYL PA 6-GF cards are available upon request in the Digimat-MX system.

Unprecedented modelling accuracy

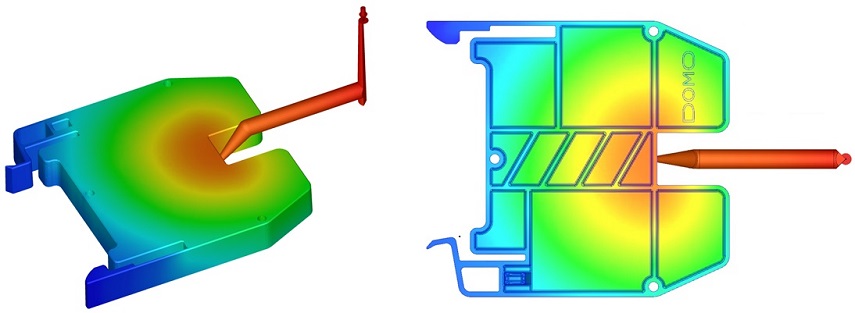

Injection filling simulation performed on electric parts

For fibre reinforced materials, advanced mechanical simulations examine the orientation of glass fibres induced by the injection process. In a concerted effort, DOMO’s R&D teams have successfully transferred their significant expertise developed in MMI integrated simulation with PA 66-GF materials to enable highly reliable predictive simulation results with the PA 6-GF resins of the TECHNYL C range.

The new MMI material cards for TECHNYL C cover a wide range of glass fibre concentrations, humidity and temperatures for elastic and elastoplastic models with failure indicators. These comply with state-of-the-art tools in Digimat and are a first step in bringing the TECHNYL PA 6 database to the same performance level as its PA 66 counterpart. Crash performance and thermal PA 6-GF models will be added soon.

New application designed for a metal substitution with PA66 thanks to MMI by DOMO SERVICE HUB

MMI material models are the end of a chain where each link has been optimised. Specifically designed procedures and meta-modelling technology take the modelling accuracy to a level that surpasses the capabilities of most conventional simulation tools and methods. Customers benefit from shorter development times and better internal cost control. This can be a key advantage in bringing stronger, lighter, safer and more cost-effective parts to demanding new markets, such as e-mobility.

DOMO’s MMI is part of the company’s encompassing customer support offering under the DOMO Service Hub, which also includes 3D printing of functional prototypes using Sinterline PA 6 powders and Application Performance Testing at fully equipped APT validation centres. Simulation is the last pillar of DOMO Service Hub, providing a CAE support on injection and anisotropic mechanical simulation to DOMO customers that do not have the necessary in-house capabilities.

Further information:

www.domochemicals.com/en/products/technyl-engineered-materials

Photo/Graphic by courtesy of DOMO