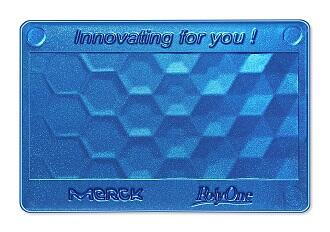

Fascinating depth effect, smooth surface

The leading science and technology company Merck will refine and market its innovative 3D plastics technology together with PolyOne in a strategic collaboration. PolyOne is a global leader in polymer materials, colorants and services. Together, the two companies want to develop this pioneering in-mould 3D (IM3D) technology and establish it in end-use markets including packaging and consumer electronics. A patent application has been filed for IM3D for plastics applications. Merck already has had success with similar 3D technology for printing on paper.

“IM3D is just the beginning of our strategic collaboration with PolyOne. Our objective in the coming years is to jointly launch additional innovative plastics technologies with pearlescent pigments”, says Michael Heckmeier, head of the Pigments & Functional Materials business unit at Merck.

The human eye perceives in the plastic a three-dimensional image that seems to come out of the flat surface, but the plastic itself is completely smooth and planar. Several processing steps were previously necessary to generate this depth effect in the polymer; now the 3D impression is created in just one step during the injection moulding process itself using the innovative technology from Merck. The striking effect turns packaging components such as caps and closures as well as plastic housings into distinctive eye-catchers.

“With the IM3D technology from Merck, brand manufacturers have an outstanding enhancement technology at their disposal to set their premium products apart from the competition”, adds Christoph Palm, vice president and general manager, Colour & Additives EMEA & India at PolyOne. “Leading brand owners from the packaging and consumer electronics industries will count among those very interested in this new technology”.