New mixing heads at K 2013

At K 2013 Cannon (hall 13, stand B76) has introduced the new versions of their high pressure mixing heads, designed to cope with the latest chemical formulations for rigid, flexible, reinforced polyurethanes and for fast RTM epoxy resins.

Fast-reacting rigid foams are progressively being adopted for the manufacture of modern refrigerators, insulation panels and pipes: their thermal insulation capacity is greatly improved by reducing the average diameter of the foam's cells, and this can be obtained with very fast-reacting formulations. As a consequence, since these end products are becoming larger and larger, these quickly-setting foams must be injected at higher output rates than in the past.

The new and redesigned versions of heads that Cannon present at K 2013 have been conceived in order to cope with the rising request from the market of faster operations, higher reliability under severe cycles conditions, reduced overall cost of ownership and ease of service and maintenance. According to the type of chosen head, their users benefit from a wide range of advantages:

- significant foam savings, thanks to higher mixing efficiency at lower working pressure;

- optimum mixing efficiency and very laminar injection at a very high output;

- superior foam's performances using low-boiling point blowing agents;

- possibility to reach remote injection holes, thanks to longer injection noses and sleek heads' exterior design;

- possibility to vary the foam's output during a multiple sequential injection, in order to wet a very long portion of the mould cavity during the deposition of the foam;

- reduced TCO (Total Cost of Ownership) thanks to long-lasting construction and smart solutions for the periodical maintenance.

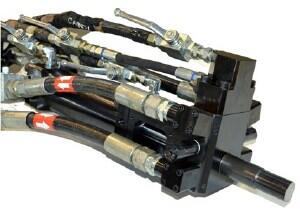

At the company stand a series of new and redesigned mixing heads is exhibited:

- JL 32 (18, 24 and 32 mm), particularly suitable for new rigid foam plants;

- FPL SR (18, 24 and 26 mm), highly recommended for the revamping of existing rigid foam plants;

- LN6 for ESTRIM, a compact and clever new patented solution, developed specifically for fast RTM technology with epoxy resins;

- AX (14,18 and 24 mm), a restyled external design provides significant advantages when foaming automatically automotive seats;

- RIM-24/4 mixing head, the compact solution for the injection of filled and reinforced formulations for RRIM;

- InterWet 30, the completely revised, patented design, provides superior wettability of the chopped glass fibres used in the InterWet coinjection process.

More than 32,000 Cannon mixing heads - most of them are still in production - have been installed on more than 14,000 metering units, in the five continents. The output capacity of these heads covers a range from 1 to 10,000 g/second, meeting and exceeding the expectations of a wide number of end users of polyurethanes, epoxy, silicone, phenolics and DCPD. Dedicated models have been specifically developed for different applications, chemical components, injection or pouring methods.