On November 13 at Formnext 2018 (Frankfurt, November 13-16) DSM announced two major product launches that will help accelerate adoption of 3D printing into mainstream production.

With Somos PerForm Reflect, DSM once again demonstrates its leadership in high-performing materials for additive manufacturing. Based on DSM's industry leading Somos PerForm, the new PerForm Reflect will again set new standards for 3D printing materials for PIV wind tunnel testing, by drastically reducing the need for post-processing of 3D printed parts.

With its new thermoplastic copolyester Arnitel ID2060 HT, DSM offers new possibilities for automotive manufacturers who are looking to 3D print structural parts that can perform in some of the most harsh circumstances. Arnitel ID2060 HT is the first 3D printing material to offer a unique balance of flexibility, chemical resistance against EGR and prolonged high temperature resistance, making it ideal for demanding automotive and industrial applications.

With the launch of Somos PerForm Reflect, DSM is bringing to market a groundbreaking new stereolithography material for wind tunnel testing with PIV (Particle Imaging Velocimetry). By eliminating the need to apply PIV coatings to the printed parts, Somos PerForm Reflect saves more than 30% post treatment.

In Formula One, typically a car body is printed at 60% of its normal size for simulation purposes and checked with particle imaging velocimetry (PIV) in critical areas. On parts printed with Somos PerForm Reflect, manufacturers can eliminate the step of applying PIV coatings.

This allows customers to reduce post processing of the parts by more than 30%, thus enabling them to collect data faster, decrease overall lead time per design iteration and conduct iterations faster.

Somos PerForm Reflect utilizes new patented technology that allows for reducing and even eliminating much of the finishing work required with traditional materials. Based on DSM’s industry standard Somos PerForm, the new resin demonstrates all the performance attributes that customers rely on such as low viscosity, low settling, fast processing and high stiffness and heat resistance.

Arnitel

ID2060 HT is DSM’s new high-performance Thermoplastic Copolyester (TPC) for 3D

printing using Fused Filament Fabrication (FFF). This filament is the first to

offer a unique balance of flexibility, chemical resistance against exhaust gas

recirculation (EGR) condensate and prolonged high temperature resistance. This

balance of properties makes the filament ideally suited for printing demanding

automotive air-fuel and industrial applications.

Arnitel

ID2060 HT is DSM’s new high-performance Thermoplastic Copolyester (TPC) for 3D

printing using Fused Filament Fabrication (FFF). This filament is the first to

offer a unique balance of flexibility, chemical resistance against exhaust gas

recirculation (EGR) condensate and prolonged high temperature resistance. This

balance of properties makes the filament ideally suited for printing demanding

automotive air-fuel and industrial applications.

Arnitel ID2060 HT is the first high performance TPC FFF material combining flexibility with prolonged high temperature use, chemical resistance and strength. Parts printed can resist sustained high temperatures of 175°C (1000 hours) or 190°C (500 hours) and chemicals such as EGR (exhaust gas recirculation) condensate.

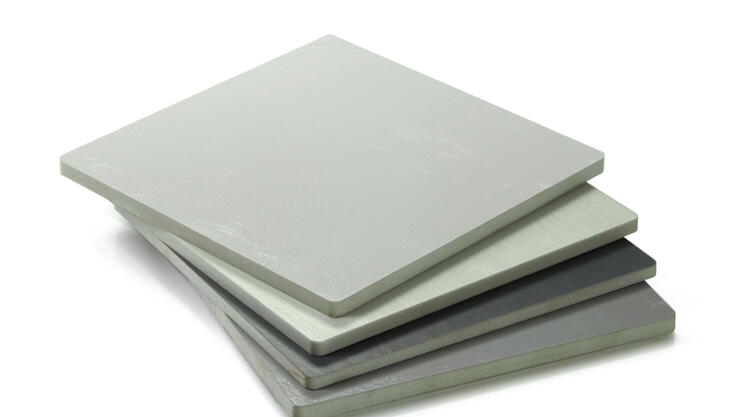

These properties make Arnitel ID2060 HT suitable for under the hood applications and components for end-of-arm tooling, such as air-fuel management systems, engine shields and covers for automotive. It allows manufacturers to replace aluminium and rubber for light weighting applications under the hood.