The rising

number of conductive compounds in state-of-the-art technological solutions

demand greater and greater control over the electrical characteristics

available in manufactured goods. This is particularly true for projects that

need to comply with Atex standards, destined for use in explosive atmospheres.

The rising

number of conductive compounds in state-of-the-art technological solutions

demand greater and greater control over the electrical characteristics

available in manufactured goods. This is particularly true for projects that

need to comply with Atex standards, destined for use in explosive atmospheres.

Atex specifications demand a precise threshold of surface resistance on the item, with a set upper limit of one billion ohm. While it is true that the problem is addressed by adopting highly conductive compounds, it is also true that a low resistance often creates electrical, mechanical or aesthetic type problems due to the presence of carbon black, carbon fibre or graphite.

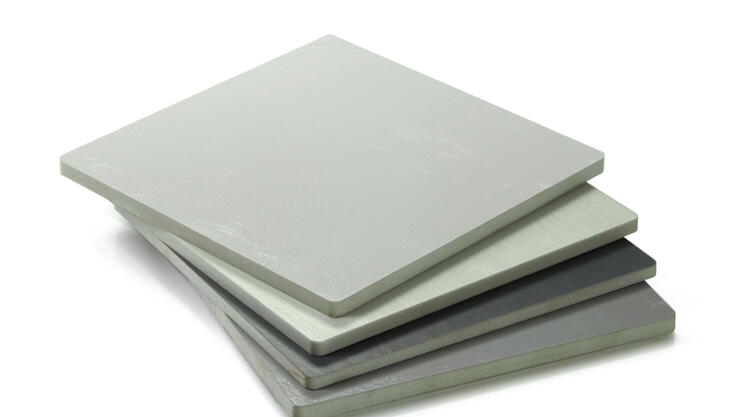

The new generation of Latiohm PD02 was developed to overcome similar issues. The strength of these materials resides in the adoption of intrinsically antistatic polymers, the purpose of which is to ensure an interval of permanent resistance of between 10 millions and one billion ohm. The compounds are developed using amorphous or semi-crystalline matrices like ABS, PP and PA for the base, reinforced where necessary to deliver excellent mechanical performance, even when cold.

The requirements associated with typical fields of use also impose excellent resistance to thermal cycles and stabilization to UV radiation, as required for example for electronic command housings for extended outdoor use, employed in building sites, in the mineral, petroleum and mining industries, and in the transportation of mineral or food powders.

A notable advantage of the PD02 formula is colourability and excellent exterior appearance made possible by the adoption of conductive polymers. No longer, then, just black articles, and the usual carbon black or carbon fibre, but also items that at last can be tailored - without any kind of limitation - to the needs of increasingly demanding technical markets, including in terms of aesthetics.

As Lati has learned from its long experience, the new Latiohm materials are often designed for simple processing without particular hurdles in terms of process or equipment. PD02 grades do not, in fact, require specific adaptations to develop moulds, and the dispersal of antistatic polymers happens spontaneously and uniformly throughout the cast mass, ensuring continuity in electrical performance throughout the manufactured item.