With the introduction of electric drives on Plastiblow (Plastimac Group) blow moulding machines, their use in the medical field has been expanded. Indeed the elimination of hydraulic drives removes a potential source of product contamination, making it possible to use the machines in clean-rooms or environments with controlled atmosphere.

One application is the production of Pasteur pipettes, a precision laboratory dropper consisting of a thin capillary tube with an engraved scale (normally from 1 to 3 ml) and a larger top part which operates as a pump.

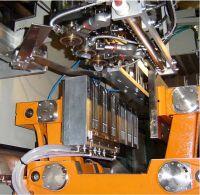

Plastiblow blow moulding machines can produce from 2,000 to 16,000 Pasteur pipettes per hour. For example, the PB2E/S single-carriage model is suitable for intermediate production levels: equipped with a 60-mm extruder and 3-outlet head, it can produce 6,500 pieces per hour.