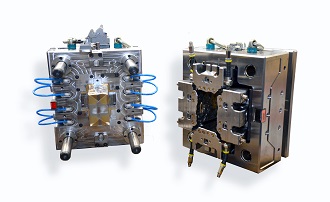

The motto “One stop for higher productivity” summarises Haidlmair’s offer. The Austrian tool manufacturer, technology and market leader in injection moulds for beverage crates, storage and logistics containers, pallets and pallet boxes, as well as recycling containers presents its options and novelties to the audience at this year’s K show in Düsseldorf.

The Haidlmair experts start out with the customer’s product idea and will optimise the mould with state-of-the-art simulation software (Haidlmair Advanced Simulations) before it enters production. The unique state-of-the-art Haidlmair machine range makes it possible to manufacture moulds of more than 80 tons. Most of the moulds produced are sampled in the in-house technical centre and delivered in perfect coordination with the customer. After delivery, the Haidlmair International Service ensures that the moulds are perfectly serviced. If an acute service need arises, service employees will be at the customer’s site without delay. This ensures maximum productivity and offers the moulder an all-round carefree package. The presentation of these productivity benefits is at the focus of the trade fair appearance of the company.

The great highlight of this year’s Haidlmair

exhibition is, however, the world premiere of a new injection-moulding

technology, a development of Haidlmair Advanced Technologies. It is an FDU

(Flat Die Unit). The FDU is the first great development synergy project of two Austrian

companies of the group - Haidlmair in Nußbach and EMO in Micheldorf. It

combines the two technologies of injection moulding (Haidlmair know-how) and

extrusion (EMO know-how). The FDU is an open hot-runner nozzle system that is

installed in the injection mould. A distribution channel in the nozzle has been

modified accordingly and projected onto a flat nozzle. The material flow

therefore differs from the conventional injection moulding procedure.

The great highlight of this year’s Haidlmair

exhibition is, however, the world premiere of a new injection-moulding

technology, a development of Haidlmair Advanced Technologies. It is an FDU

(Flat Die Unit). The FDU is the first great development synergy project of two Austrian

companies of the group - Haidlmair in Nußbach and EMO in Micheldorf. It

combines the two technologies of injection moulding (Haidlmair know-how) and

extrusion (EMO know-how). The FDU is an open hot-runner nozzle system that is

installed in the injection mould. A distribution channel in the nozzle has been

modified accordingly and projected onto a flat nozzle. The material flow

therefore differs from the conventional injection moulding procedure.

The plastic flows evenly into the cavity through a long, narrow gap. The FDU combines the benefits of injection moulding and extrusion. The shear in the nozzle is reduced by up to half, which in turn considerably reduces shear warmth. In some materials, such as polypropylene, a lower injection pressure can be achieved as well. The homogeneous output of the material due to the slot geometry expands the process window for injection, holding pressure and cooling. All of these items permit a drastic reduction of the cycle time, which in turn has the corresponding positive effect on productivity.

The new technology is shown in action at three machine manufacturer stands:

- Milacron

(stand C06, hall 15) - The German/American manufacturer of

complete systems for plastics processing produces a “miniature wrinkle box”,

equipped with the FDU technology. The mould is filled via 2 injection units.

The wrinkle box is particularly attractive thanks to its new, reproducible

colour design

- Stork IMM (stand D72, hall 13) - The Dutch manufacturer of injection moulding systems produces a standard meat box with a Haidlmair high-performance mould equipped with FDU; it is characterised by its particularly short cycle time

- Wittmann Battenfeld (stand D22, hall 16) - The stand of this company offers a special highlight. The “soft wrinkle bag” has its world premiere there. It is the latest member of the wrinkle box family that Haidlmair presented for the first time at K 2010. It is characterised by a new design and particularly by the TPE material that gives the bag its soft feel. The benefits of FDU technology are outstandingly evident here as well.