At the 2019 K, US-based Barnes Group is exhibiting in Europe and for the first time showcasing its Molding Solutions strategic business unit at a joint booth. Barnes Molding Solutions - including brands Foboha, Gammaflux, männer, Priamus, Synventive and Thermoplay - covers the entire spectrum of mould making and hot runner technology, including temperature control and process control technology.

The booth concept dispenses with the presentation of individual brands and focuses entirely on customer application. Theme-based sections will present solutions for demanding projects concerning the manufacture of plastic parts in the medical/pharmaceutical, personal care, packaging, automotive and technical parts markets, as well as electrical and household applications.

Clear brand profiles and intensive collaboration

Barnes Molding Solutions has used the last few years to enhance the profiles of its individual brands while simultaneously strengthening the collaboration between them. Molding Solutions’ strategy ensures that each brand of the company focuses on the development of its core competencies while close cooperation between the brands provides the customer with the best solution for the respective application.

Reliability and cost-effectiveness in production

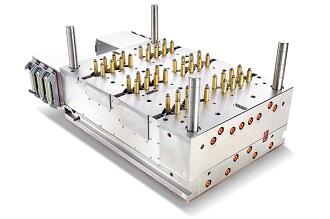

Foboha and männer, Barnes Molding Solutions’ high-precision mould makers, serve different industries but work according to the same principles in terms of performance, durability, and ease of maintenance of their tools. While männer specializes in moulds for the medical and pharmaceutical industries with corresponding knowledge in qualification, FOBOHA develops innovative mould concepts for the personal care and caps and closures end markets. FOBOHA will present two cube technology innovations at the 2019 K trade show: the Plug ‘n Play Compactcube for rapid implementation and easy maintenance, as well as its Reversecube, a system of counter-rotating cubes on an Arburg injection moulding machine, which replaces several moulding machines and automated assembly units with a single system.

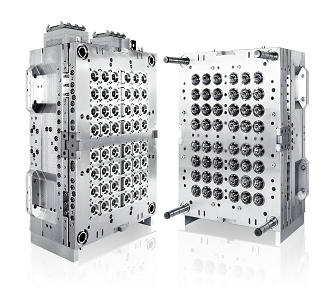

In hot runner technology, männer, Thermoplay, and Synventive will exhibit their very latest developments and projects in their sectors. männer continues to focus on its Cylindrical Valve Gate patented by company founder Otto Männer, while Thermoplay specializes in thermal system designs. The two hot runner specialists complement each other to meet specific customer requirements. Thermoplay will present its new range of hot runner systems for multicavity moulds with up to 144 cavities. The new systems offer significant process window improvements and an optimized thermal profile, which reduces energy consumption. This helps to ensure high reliability of the injection moulding process and consistent part quality, even at the high speed and volumes specifically required for caps and closures, packaging, and personal care applications.

In hot runner technology, männer, Thermoplay, and Synventive will exhibit their very latest developments and projects in their sectors. männer continues to focus on its Cylindrical Valve Gate patented by company founder Otto Männer, while Thermoplay specializes in thermal system designs. The two hot runner specialists complement each other to meet specific customer requirements. Thermoplay will present its new range of hot runner systems for multicavity moulds with up to 144 cavities. The new systems offer significant process window improvements and an optimized thermal profile, which reduces energy consumption. This helps to ensure high reliability of the injection moulding process and consistent part quality, even at the high speed and volumes specifically required for caps and closures, packaging, and personal care applications.

männer, Foboha, and Thermoplay represent the multicavity team within the Barnes Molding Solutions strategic business unit, serving the market for medium- and high-cavity applications. The key strength of these three multicavity experts is several decades of experience with molds and hot runner technology as well as knowledge about their technical interaction. In addition, the hot runner division benefits from the extensive application knowledge of the mould makers, which allows them to recommend the optimal hot runner design solutions to customers. The best technical and process-stable production solution requires an integrated system from a single source.

Synventive, primarily serves the automotive, industrial, electronics, and household goods industries, with solutions tailored to those sectors. For the first time at a European trade fair, Synventive will present its new generation eGate system. The electric-drive valve gate solution is now available for larger components and ensures complete pin movement control on each individual nozzle to achieve the highest performance for perfect component surfaces and dimensional consistency. A live demonstration of the proven SynFlow two-speed pin control technology will also be presented. SynFlow for hydraulic cascade moulding now offers even more melt flow control functionality and has been equipped with a new interactive user interface.

Synventive, primarily serves the automotive, industrial, electronics, and household goods industries, with solutions tailored to those sectors. For the first time at a European trade fair, Synventive will present its new generation eGate system. The electric-drive valve gate solution is now available for larger components and ensures complete pin movement control on each individual nozzle to achieve the highest performance for perfect component surfaces and dimensional consistency. A live demonstration of the proven SynFlow two-speed pin control technology will also be presented. SynFlow for hydraulic cascade moulding now offers even more melt flow control functionality and has been equipped with a new interactive user interface.

Quality assurance in the injection molding process

Within the area of control and regulation, Barnes Group has two companies with industry-leading expertise in its portfolio: Gammaflux is a specialist in the field of temperature control, and Priamus – the control technology pioneer – ensures optimum process control with its FillControl and state-of-the-art sensor elements.

A central topic is the process control of biopolymers and recycled materials, in which the inevitably higher process fluctuations are automatically regulated and compensated.

Priamus will present its Quality Monitor, a production-optimized solution for process monitoring that incorporates the industry standard OPC-UA networking interface as part of all Priamus systems.

Gammaflux will also present several integrated solutions in its G24 temperature controller. The first system is a hydraulic power unit (HPU) integrated into a G24, an HPU for controlling hydraulic valve gate systems and an integrated cascade control (SVGC). The second system integrates the männer e-control (servo control) in a G24 temperature controller. Customers benefit from a small controller footprint and only one operating console. Together with Priamus, Gammaflux integrated the Quality Monitor quality assurance monitoring software within the G24 controller.

Gammaflux will also present several integrated solutions in its G24 temperature controller. The first system is a hydraulic power unit (HPU) integrated into a G24, an HPU for controlling hydraulic valve gate systems and an integrated cascade control (SVGC). The second system integrates the männer e-control (servo control) in a G24 temperature controller. Customers benefit from a small controller footprint and only one operating console. Together with Priamus, Gammaflux integrated the Quality Monitor quality assurance monitoring software within the G24 controller.

The combination of expert knowledge and experience in moulds and hot runner technology, and temperature and process control at this year’s K trade fair will make it possible to convincingly demonstrate one of the most important topics for the industry and the global society. environmentally friendly plastics. These types of bio-plastics have long been recognized as important by Barnes Molding Solutions and will be highlighted at the trade fair with a dedicated theme-based section. In addition to customer projects that have already been completed, the strategic business unit will provide insight into its work in the extensive field of biologically produced, biodegradable, or even post-consumer recycled plastic (PCR).