Sacmi technology for Parmalat milk

Sacmi-developed innovation has won over Parmalat (Lactalis Group), which has now chosen the IPS (injection preform system) platform to renew its Piana di Monteverna (Caserta) plant. Here, as of today, PET preforms are being manufactured for the milk sector, providing the lightest. highest-performing 1-litre bottles on the Italian market.

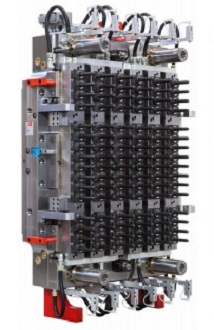

Developed with the clear aim of offering customers a complete, integrated platform that stands out from alternative solutions on account of its user-friendliness and fast, easy size changeover, the IPS 220 features some great design innovations on the mould clamping unit which - thanks to intense design work involving FEM techniques to optimise mechanical inertia - ensures ultra-fast lock-to-lock times, thus shortening preform production cycles.

A key feature on the solution installed by

Parmalat is the all-Sacmi mould. This complete 48-cavity injection mould (hot

half and cold half) stems from painstaking in-company design of each component

and is characterized by optimized channels inside the hot chamber, plus

high-efficiency cooling circuits; the latter facilitate heat exchange to

provide ultra-high performance production cycles, as already demonstrated

during the simulation and testing carried out jointly by the Sacmi research centre

and the Parmalat R&D facility.

A key feature on the solution installed by

Parmalat is the all-Sacmi mould. This complete 48-cavity injection mould (hot

half and cold half) stems from painstaking in-company design of each component

and is characterized by optimized channels inside the hot chamber, plus

high-efficiency cooling circuits; the latter facilitate heat exchange to

provide ultra-high performance production cycles, as already demonstrated

during the simulation and testing carried out jointly by the Sacmi research centre

and the Parmalat R&D facility.

The plant supplied to Parmalat is no mere machine. One of the key factors in the Group's investment choice was "Sacmi Total Care", the Sacmi system that, thanks to advanced system-integrated web-connected sensors, allows remote, predictive performance and process monitoring, anticipating problems and providing appropriate solutions (e.g. sending spare parts and troubleshooting the most common issues on the line) without having to send a specialised technician on-site. Fully integrated and connected - from press to dryer, refrigeration systems to compressor - the system can be monitored both remotely and from any device connected to the corporate network, anticipating every possible need (spare parts provisioning, maintenance tasks) and minimizing production downtimes.

The result, an intelligent production model that looks to "Industry 4.0", the strategy that - via the use of advanced sensor systems and IT technologies - provides an innovative approach to product and service, ensuring the cream of Italian industry has a decidedly bright future.