Prototyping more rapid and economic thanks to 3D printing

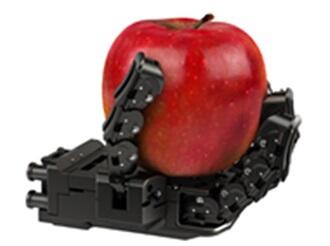

The 3D printing and additive manufacturing solutions company, Startasys has announced that Italian company, qbrobotics, is producing customized sample robotics much more quickly and cost-effectively than via traditional methods, using its Fortus 250 3D printer.

Using Stratasys’ high-endurance ABSplus 3D printing material, the company, a pioneer in the next generation of soft robotics, has reduced its prototyping costs of its portfolio by 90% since introducing 3D printing in-house.

“Our robotics play a direct role in peoples’ lives and this, by its very nature, demands extensive research and functional testing to ensure that they pass the required safety regulations. 3D printing allows us to develop robotics with the best functionality, ergonomics and aesthetics to meet the individual customer’s requirements - without the usual and considerable time and cost issues”, says Fabio Bonomo, CEO and electronics designer, qbrobotics.

With the ability to pinpoint design flaws early in the production process, qbrobotics has streamlined its workflow and eradicated the subsequent rework, which traditionally increases the time-to-market and labor costs further along the production line. Any design iterations can be implemented in a matter of days compared to the company’s previous process of three weeks.

“In our industry, time costs money and since integrating 3D printing within our design process, we can produce personalized, fully-functional prototypes 85% faster than our previous methods. Crucially, we’re able to achieve this without compromising on the quality or functionality of the robotics for performance evaluation”, Bonomo explains.

“qbrobotics represents a great example of how 3D printing provides product designers with complete flexibility and cost-effective design freedom. In industries where customization is integral - in this case robotics - this enables companies to save time and money while developing more advanced, functional prototypes”, Giuseppe Cilia, Stratasys’ Italian sales manager concludes.