The "new" KraussMaffei: sustainable solutions and climate neutrality within 2030

At the trade show K 2022, the company will reaffirm its claim to expand its market position as a leading supplier of sustainable solutions for the plastics industry. The company's 185th anniversary in 2023 also marks the beginning of a new, sustainable era: in eight years, i.e. in 2030, the entire company will be climate-neutral.

The new plant in Laatzen and the new group headquarters in Parsdorf near Munich will meet the highest environmental standards. This means modern building technology with one of the largest roof-mounted photovoltaic systems in Europe, a combined heat and power plant, heating and cooling sails in the offices, active hall ventilation and intelligent LED lighting with light and motion sensors. Both sites are certified according to the DGNB system (German Association for Sustainable Building).

In order to achieve the ambitious sustainability goals, the circular economy is a supporting pillar of KraussMaffei's corporate strategy. As a recycling pioneer, the company already has more than three decades of experience in researching as well as developing the preparation and reprocessing of recycled plastics. Customers have already recycled more than one million tons of plastics with the help of their KraussMaffei systems. To this end, KraussMaffei offers its customers state-of-the-art recycling technologies and digital solutions - ideal for the business models of our time. KraussMaffei relies on mechanical as well as solvent-based and chemical processes. These enable customers to achieve higher energy efficiency in production, waste reduction and circular economy with recycled material.

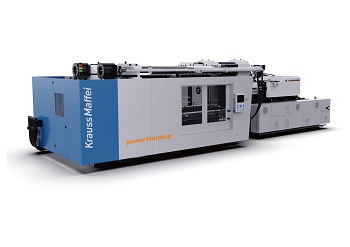

Moreover, the company is continuously improving the design of its products to achieve consistent or even improved product quality with less energy and material input. Some of its innovative solutions will be on show at K 2022: the new precisionMolding and powerMolding injection molding machine series, the new DCIM (Direct Compounding Injection Molding) ZE Blue Power, and digital solutions such as APCplus and socialProduction. This is also reflected in the order intake. In the first quarter of 2022, order intake was just under 370 million euros, an increase of 27% compared to the prior-year quarter.

Moreover, the company is continuously improving the design of its products to achieve consistent or even improved product quality with less energy and material input. Some of its innovative solutions will be on show at K 2022: the new precisionMolding and powerMolding injection molding machine series, the new DCIM (Direct Compounding Injection Molding) ZE Blue Power, and digital solutions such as APCplus and socialProduction. This is also reflected in the order intake. In the first quarter of 2022, order intake was just under 370 million euros, an increase of 27% compared to the prior-year quarter.

Starting with the new precisionMolding and powerMolding injection molding machines, the new precisionMixhead and the newly named purity recyclingLine (formerly edelweiss), KraussMaffei is introducing a new system for naming its products. Instead of independent approaches per technology area, machines and products will in future be named according to a uniform descriptive system. In future, products and machines in the New Machines Division will receive one of four name suffixes: pioneer for lines and system solutions, purity for products in the circular economy sector, power for hydraulic injection molding machines and extruders, and precision for electric injection molding machines, automation and downstream products like mixing heads or pipe heads.

The new precisionMolding is the basic, all-electric PX series machine with a reduced number of options, while powerMolding is the counterpart of KraussMaffei's proven hydraulic GX series. Both precisionMolding and powerMolding are ideal for standard applications, for example for technical parts, electric and electronic devices, and the automotive, packaging or medical industry. The precisionMolding was introduced in Asia in 2019, the powerMolding 2021. Both series have established themselves very successfully in that region. Customers in these markets particularly appreciate the high level of precision and high performance level as well as the rapid availability and ease of operation. And this is available at an outstanding price/performance ratio. With the K 2022 launch, the precisionMolding and powerMolding are now also gaining entry into markets in Europe and North America.

Both the precisionMolding and powerMolding stand for high efficiency and profitability that meet the familiar KraussMaffei quality standards. For example, a selected range of options, including a wide variety of mold installation heights or the easy integration of automation solutions, let you configure customized system solutions quickly. Depending on the application of the powerMolding, the boost in throughput can amount to as much as 15 percent over comparable standard injection molding machines on the market. This is ensured by the short dry cycle times, the high shot weight consistency and the associated low scrap rates.

Both the precisionMolding and powerMolding stand for high efficiency and profitability that meet the familiar KraussMaffei quality standards. For example, a selected range of options, including a wide variety of mold installation heights or the easy integration of automation solutions, let you configure customized system solutions quickly. Depending on the application of the powerMolding, the boost in throughput can amount to as much as 15 percent over comparable standard injection molding machines on the market. This is ensured by the short dry cycle times, the high shot weight consistency and the associated low scrap rates.