Injection moulding, digital printing and quality control for closures

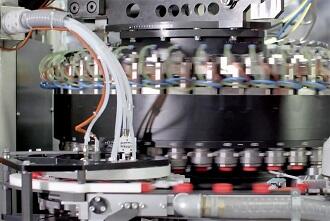

Following the success of the 2016 edition, Sacmi will be taking part for the second time in the Prodexpo fair in Moscow (February 6-10). This international fair is dedicated to technology for the food and beverage industry and covers everything from raw materials to processing and packaging. A leading designer of complete PET processing lines and the world-leading supplier of plant engineering solutions for the manufacture of plastic caps using compression technology, Sacmi has progressively extended its product range to ensure a prompt response to market needs. In this field, new additions to the Sacmi range include the new CCM 24 SC, a compression press capable of producing 1,000 caps per hour with just 24 cavities. Compact and high-performance, it comes complete with a system for timed slitting of the anti-tamper band while integrated quality control provides a response to customers’ investment requirements - even those of small-medium businesses who have no intention of missing out on the guarantees and outstanding quality provided by Sacmi technology.

Downstream

from the CCM, Sacmi proposes the new Colora Cap, the revolutionary cap digital

printing system that allows HD application of any decoration on plastic caps.

Freely programmable - with up to 10 million images - the machine impresses the

chosen decoration on the cap with scans lasting just 2 tenths of a second,

ensuring a clear response to beverage manufacturers’ burgeoning need to bring

out the best in both product and brand; this goes hand in hand with further

developments on the coloured cap front (with the use of, in place of

traditional coloured grains, liquid colorants that act on a neutral molten

plastic base, thus making colour changeovers much faster).

Downstream

from the CCM, Sacmi proposes the new Colora Cap, the revolutionary cap digital

printing system that allows HD application of any decoration on plastic caps.

Freely programmable - with up to 10 million images - the machine impresses the

chosen decoration on the cap with scans lasting just 2 tenths of a second,

ensuring a clear response to beverage manufacturers’ burgeoning need to bring

out the best in both product and brand; this goes hand in hand with further

developments on the coloured cap front (with the use of, in place of

traditional coloured grains, liquid colorants that act on a neutral molten

plastic base, thus making colour changeovers much faster).

One of just a handful of firms in the world that leads the way in different sectors and technologies, Sacmi also provides an integrated solution for the converter world thanks to the IPS platform, now even higher-performing and more flexible following the introduction of the new IPS 400 injection press and the imminent launch of the new IPS 300; the latter completes a range of solutions that covers every possible size requirement, maximising versatility while minimising mould and size changeover times.

At Sacmi

technological excellence - with tip-top productivity, ultra-low consumption and

outstanding versatility - is accompanied by cutting-edge total quality control

thanks to inspection systems designed and marketed by the Group’s Automation

& Inspection Systems Division. This means Sacmi can now complement PVS

preform inspection systems - designed to operate both on the line at ultra-high

speed and off-line or in research labs - with a complete range of systems for

quality control of container and label plus advanced line supervisors (such as

the all-new Here (Human expertise for reactive engineering); the latter allow

manufacturers, thanks to latest-generation software and advanced on-machine

sensors, to effect real-time monitoring of production and receive remote

assistance from a specialised Sacmi technician to solve common problems.

At Sacmi

technological excellence - with tip-top productivity, ultra-low consumption and

outstanding versatility - is accompanied by cutting-edge total quality control

thanks to inspection systems designed and marketed by the Group’s Automation

& Inspection Systems Division. This means Sacmi can now complement PVS

preform inspection systems - designed to operate both on the line at ultra-high

speed and off-line or in research labs - with a complete range of systems for

quality control of container and label plus advanced line supervisors (such as

the all-new Here (Human expertise for reactive engineering); the latter allow

manufacturers, thanks to latest-generation software and advanced on-machine

sensors, to effect real-time monitoring of production and receive remote

assistance from a specialised Sacmi technician to solve common problems.