Fast assembling and disassembling for a wide application range

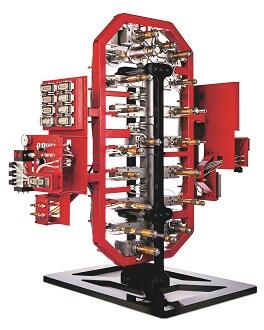

A number of additions and enhancements have been rolled out by Mold-Masters (hall 22, stand C141/D142 at Plast 2018) to Fusion-Series G2, the drop-in system favoured by the automotive industry for high-quality large part production. Maximized for uptime, the Fusion-Series G2 hot runner system is delivered completely pre-assembled and pre-plumbed, saving significant set-up time in order to get back into production right away. Incorporating popular features like field replaceable heater bands ensures that any maintenance is quick and easy. Capable of shot sizes from less than 15 g to over 3,500 g, Fusion G2 is favoured by automotive, appliance, logistic packaging, and similar industries focused on producing medium to large high-quality parts. These systems also come fully supported by Mold-Masters global network. New are the F3000 and F8000 nozzles which expand the capabilities and applications of this system. F3000 has a shot capacity of less than 15 g, which is ideal for smaller under hood components, technical automotive components and price sensitive packaging and consumer good applications. The F8000 increases shot capacity of the system further than ever before to 5,000 g by utilizing runner diameters up to 28 mm. Nozzle lengths are also available that exceed 1 m. F8000 has been developed to meet the processing requirements of common large automotive components like fascias, instrument panels, door panels and also large white goods. Also new is the second generation of the Melt-Cube side gating hot runner that allows simultaneous direct side gating of up to 8 cavities per Cube for high cavitation moulds. Based on a successful advanced side gating technology this version features a simplified design making it easier to maintain and service. Tips are clamped by a single bolt in sets of 2 (not entire assembly) which reduces assembly/disassembly times by up to 85%. Manifolds can be accessed from the parting line and tips are located to gate. As with many Mold-Masters products this Melt-Cube also incorporates Brazed Heater Technology for precise thermal profile for enhanced processability and superior reliability that often outlasts the life of the mould. Melt-Cube is known for its excellent vestige control, low-pressure drop and precise cavity-to-cavity rheological balance. Its side gating eliminates wasteful sub-runners and offers higher pitch density than circular systems for greater production output. Perfect for deep draw medical parts such as pipette tips, syringe barrels, needle shields or parts where only side gating is permitted.