Profiles in recycled PA for the thermal break

At MADE Expo, the exhibition dedicated to architecture, design and building which took place in Milan from 2 to 5 October, Ensinger unveiled the new Insulbar RE thermal insulating profiles entirely made of recycled polyamide. Today, high-performance heat-insulating doors and windows play a fundamental role in the building industry, since they allow energy savings as well as a reduction of carbon dioxide emissions into the atmosphere. Embedding plastic profiles between the internal and external shells of metal frames cuts the conductivity of doors and windows, thus avoiding heat loss and ensuring considerable savings on heating and/or air conditioning costs. To this purpose, Ensinger was already offering its Insulbar plastic profiles which, with the addition of the new range, has been developed further in terms of its environment friendly features: the new products are made of recycled polyamide, subjected to an "upcycling" treatment which extends the material's life cycle without altering its original properties.

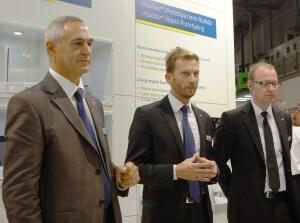

As pointed out by Giancarlo Piatti, general manager of Ensinger Italia, Daniele Saibene, sales director Italy at Insulbar, and Frank Killinger, Insulbar sales director, the production process of the rPA resin, which is wholly compounded by Ensinger, ensures the compliance with the strict DIN ISO 9001: 2008 standards that the Insulbar range is required to meet. The material's composition and properties are carefully verified and documented at each process stage: this guarantees that the new range, besides delivering high energy efficiency, confirms the same excellent mechanical properties, durability and long-term operating safety as the traditional Insulbar profiles.

The rPA insulating profiles offer doors and windows manufacturers and installers a solution enabling them to effectively meet both present and future needs. Today, for example, when the construction of public buildings or major investment projects are involved, quality marks are awarded within the DGNB, LEED or other certification systems, identifying the whole construction work as well as the building materials employed from an ecological, economical and functional point of view. Though it is slightly more expensive, Insulbar RE offers a real competitive edge, especially in contracts focusing on optimum ecological balance, reaching the equilibrium between economics and environment protection.