Silk screen technological evolution and high versatility in one line

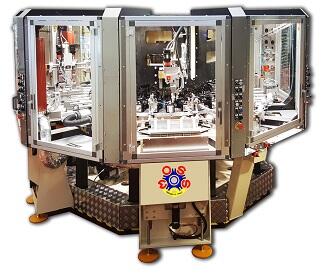

The MS1070 silk screen machine by Moss has been successfully tested in recent days by an Italian manufacturer of cosmetic and pharmaceutical articles for the decoration and assembly of dosing syringes. This machine is part of the Moss servo-driven system family, which allow a good setup control of both machine and its devices and make production handling easier. Moreover, it shorten time of changeover compared to mechanically controlled machines, thanks to few mechanical setup needed.

Piece-holding mandrels are connected in series and are controlled by B&R servomotors, Austrian leader in the field of industrial automation, project partner of all Moss machines. Silk screen heads mount B&R servomotors as well, its instant acceleration allows an absolute accuracy in printing start and stop.

The MS 1070 is suitable for decoration of cylindrical items of various sizes as it is equipped of an electrical horizontal mandrel-holding turret. Size and number of modules are designed according to customer needs. Its main advantage is the number of devices available to be installed on the machine.

Evidence of the high versatility of the line is given by the fact that in these days an Italian customer, leader in cosmetic and pharmaceutic item manufacturing, successfully tested a MS 1070 for syringe decoration and assembling. This MS 1070 has been totally customized, as it is equipped with an extra feeding system to mount syringe body on decorated pistons. A high resolution camera checks the proper assembly. An additional feeding system allows mounting of a protective cap on the dosing syringe. The line offers a quality control system manufactured by the Italian company DecoSystem as well as an UV ink drying system.