New contactless magnetostrictive position transducer

The new magnetostrictive position transducer Hyperwave is presented by Gefran at K trade fair as ideal solution for applications where maximum precision and repeatability of the measurement is required.

Mauro Parzani, Gefran Sensors Product Manager states: “Gefran boasts a consolidated know-how, which is the result of over 50 years of experience in the development and production of position sensors, with more than one million components installed. The ability to internally produce the sensing element of our transducers guarantees accuracy and precision in the measurement while ensuring high customisation flexibility". Parzani concludes: "Constant investments in R&D together with a close collaboration with the mechanical and electronics departments of the most prestigious Italian universities bolstered Hyperwave’s conception, whose name evokes the operational technology of the magnetostrictive system by means of a sonic wave with excellent performances".

Hyperwave detection system ensures a repeatability of 0.01 mm (one hundredth of a millimetre) with a very low non-linearity error of 0.01%/FS and a resolution of less than 0.5 µm, also operating at extreme temperatures from -30 to +90°C. The amplification of the primary element’s signal, 15 times greater than traditional models, renders the contactless transducer immune to the typical industry electromagnetic fields, guaranteeing precise and continuous operation over time. In detail, HYPERWAVE boasts a high tolerance to vibrations (15g/ 10 ÷ 20,000 Hz) and to shocks (100g - 11ms - single strike). Finally, the waterproof case ensures an IP67 level of protection, contributing to make this system ideal for use in harsh industrial environments.

No maintenance needed and long working lifetime: these are the strengths of the new Gefran solution compared to traditional measurement systems. By virtue of the magnetostrictive technology, the position is identified by the interaction between two magnetic fields: the first is electrically generated along the entire transducer and it interacts with the second, consisting of a cursor - with a sliding or floating design - equipped with a permanent magnet. The elimination of mechanical contact makes the system nearly immune to wear, thus significantly reducing downtimes.

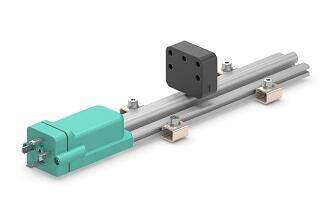

The complete range consists of two macro-categories: WP (Profile Magnetostrictive Position Transducer) with profile mechanics mounted with brackets directly on the structure to be measured, and WR (Rod-style Magnetostrictive Position Transducer) with 10 mm rod mechanics in AISI 316L stainless steel, that are mainly installed inside hydraulic cylinders with operating pressures up to 350 bar, to detect the position of the piston in real time. Transducers with WR rods can also be used as tank level meters, thanks to the magnetic float cursor. Both categories are available in three different options: General, with stroke up to 1,500 mm, Plus up to 2,500 mm and Advanced up to 4,000 mm. In addition, Gefran offers special versions: MK4-C and MK4-P can simultaneously detect up to 4 independent positions on the same transducer through a microprocessor used to detect the position of the different cursors and to operate a self-diagnosis of the transducer itself. The available outputs are analogue current/voltage, SSI and the main fieldbuses, such as Profinet, Profibus and CANopen, with a position update rate of 1kHz, i.e. over 1,000 times per second, for the best precision and a maximum level of repeatability.

Edoardo Zilioli, Gefran Sensors Product Marketing Manager comments: “Hyperwave is the new name for excellence in magnetostrictive technology. Thanks to its precision, reliability, robust and compact design, this solution can be used in various fields of application, including injection moulding, robotics, hydraulic presses, foundries, die-casting and wind generators". He concludes: “With this high-performance range of industrial sensors, Gefran confirms its commitment towards continuous product innovation. A Company whose core feature is being a one stop supplier, able to collaborate closely with OEMs and System integrators for customised systems based on individual needs".

Edoardo Zilioli, Gefran Sensors Product Marketing Manager comments: “Hyperwave is the new name for excellence in magnetostrictive technology. Thanks to its precision, reliability, robust and compact design, this solution can be used in various fields of application, including injection moulding, robotics, hydraulic presses, foundries, die-casting and wind generators". He concludes: “With this high-performance range of industrial sensors, Gefran confirms its commitment towards continuous product innovation. A Company whose core feature is being a one stop supplier, able to collaborate closely with OEMs and System integrators for customised systems based on individual needs".