VinylPlus: 20 years of progress towards circular PVC

At the completion of its second 10-year Voluntary Commitment to sustainable development, the European PVC industry takes stock of its achievements and looks ahead to 2030. Among the main results, which are summarised in the VinylPlus Progress Report 2021 published on May 17, the continuous development of collection and recycling schemes for PVC waste across Europe, which made possible to recycle 6.5 million tonnes of PVC since 2000; the progressive replacement of the most problematic additives; the reduction of energy consumption in production processes; and the development of the VinylPlus Product Label. Looking ahead, VinylPlus confirms its strong engagement and commitments to recycle 900,000 tonnes of PVC per year by 2025, in line with the ambitions of the Circular Plastics Alliance, and one million tonnes by 2030.

Over the past 20 years, the European PVC industry, through VinylPlus, has made steady progress in terms of product stewardship, research into innovative technologies and improvement of the environmental footprint of PVC. Above all, advances have been made in recycling, with the set-up of collection and recycling schemes that were virtually non-existent 20 years ago.

Since then, VinylPlus has proven to be a frontrunner in the circular economy by ensuring continuously growing and safe recycling of PVC and was well on track to meet its recycling target of 800,000 tonnes per year by 2020 prior to the Covid-19 pandemic. Despite the challenges faced by the industry in 2020, VinylPlus still achieved a great result, reaching more than 730,000 tonnes of PVC recycled and re-used into new products - above 91% of the programme’s 2020 target. Since 2000, the European PVC industry has recycled 6.5 million tonnes of PVC into new products - thus preventing the release of nearly 13 million tonnes of CO2 into the atmosphere - and created 1,500 direct jobs in recycling plants.

VinylPlus goes further than the Circular Economy, having addressed other sustainability topics such as energy efficiency, sustainable material sourcing and production, and the responsible use of additives. The energy needed to produce one tonne of PVC resin decreased by an average of 9.5% between 2007-2008 and 2015-2016. In the same period, CO2 emissions were reduced by 14.4% for the average PVC production. For converters, across main applications such as window profiles, pipes, flooring and films, energy consumption decreased between 16% and 26.5% in 2020 compared to 2010.

The Additive Sustainability Footprint (ASF) methodology developed in collaboration with The Natural Step was peer-reviewed by Life Cycle Analysis experts and validated. It helps additive manufacturers self-assess the sustainability of their current and new additives used in PVC products.

The VinylPlus Product Label, the sustainability mark for PVC products in the building and construction sector “not only provides specific criteria for more sustainable PVC production and use - said Stijn Brancart, Expert in Circular Construction at Vibe - but also opens up discussion and stimulates producers to apply the principles through different approaches. It focuses on recycled content and upcycling potential but also contains aspects of demountability and even return policies.” To date, the VinylPlus Product Label has been awarded to 128 PVC products, guiding consumers and public buyers towards more sustainable purchase decisions.

Since 2019, VinylPlus has been a signatory of the Circular Plastics Alliance, the European Commission’s multi-stakeholder platform aimed at boosting the market for recycled plastics to 10 million tonnes by 2025, and chaired the Construction Working Group.

“I am very pleased with the commitment and the proactive role of VinylPlus in the Circular Plastics Alliance - said Kirsi Ekroth-Manssila, Head of Unit, DG Grow, European Commission - I am confident that with the cooperation of all the members of the Circular Plastics Alliance, and with the positive example set by VinylPlus - as an effective and successful cross-value chain platform - the overall outcome will be a success. VinylPlus is a perfect example of how to make the Circular Economy a reality, being the first value chain in 2000 to take on the challenge of transforming a problem into an opportunity”.

As a united value chain, VinylPlus accomplished major achievements. Nevertheless, we cannot stay still. In the past months, the entire PVC value chain, together with its stakeholders, worked hard to build its next Commitment to sustainable development for the decade to 2030, which will be officially launched at the VinylPlus Sustainability Forum 2021 #Towards2030.

As a united value chain, VinylPlus accomplished major achievements. Nevertheless, we cannot stay still. In the past months, the entire PVC value chain, together with its stakeholders, worked hard to build its next Commitment to sustainable development for the decade to 2030, which will be officially launched at the VinylPlus Sustainability Forum 2021 #Towards2030.

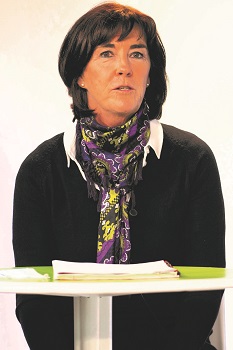

“Looking back, we have achieved a lot - commented Brigitte Dero (in the picture pn the right), Managing Director, VinylPlus. However, there is still much more to do, especially if we intend to proactively contribute to the UN Sustainable Development Goals. We now move forward to the next stage of our commitment to sustainable development, exploiting 20+ years of lessons learned and achievements to build a new and even more ambitious commitment for the next decade so as to contribute further towards a more sustainable and circular future. We look forward to the official launch of our next 2030 commitment at our VinylPlus Sustainability Forum on 17 June and to engaging with all stakeholders in this effort”.