The best way to predict the future is to simulate it

With its Engineering Service, RadiciGroup is a partner in innovative projects and the development of new products made of polymeric materials.

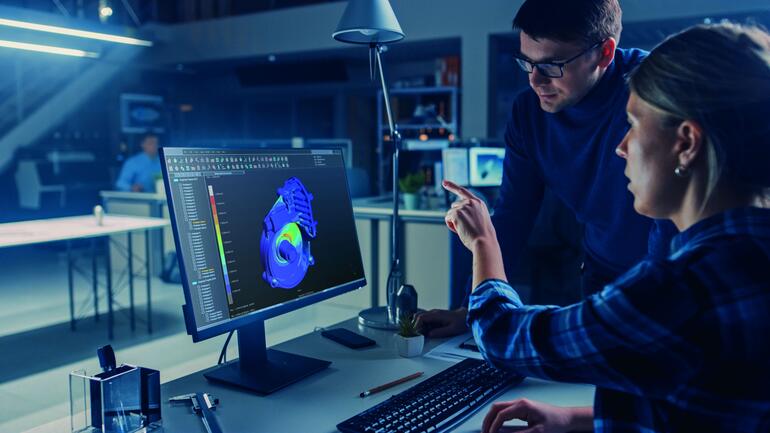

Adding the most advanced computer numerical simulation systems to the skills and experience of RadiciGroup specialists sums up to the Group’s ability to virtually reproduce the moulding process of a potential material and the stresses (mechanical, thermal and others) that the component is subjected to during use.

RadiciGroup High Performance Polymers' Engineering Service allows for predicting the behaviour of products right from the very early stages of their development, in order to optimize the design, also with a view to ecodesign and environmental performance.

Designing with engineering polymer materials to achieve demanding performance, lightweighting and sustainability targets becomes much more accessible, timely and cost-effective by using reliable computer-aided simulation tools for the prediction of processing behaviour, as well as real-world capabilities.

Readily available for RadiciGroup customers, the Engineering Service is aimed at fuelling the success of innovative projects, including metal replacement, in which the Group's engineering polymers can be used to ensure the performance required by the applications. The possibility of using polyamide as a substitute for metal, thanks to its characteristics of structural and thermal resistance even at high temperatures, ease of transformation and competitive price, is increasingly being taken into consideration - owing to the reliability of computer-assisted simulation - in numerous markets, primarily in the automotive sector.

RadiciGroup Engineering Service makes extensive use of the most advanced CAE (Computer Aided Engineering) tools to solve design problems and minimize the "trial and error" approach, reaching the final goal by optimizing resources and time.

The workflow of a CAE study is divided into three main phases:

- Pre-processing, which involves defining objectives and inputs and then modelling the case;

- Analysis, that is, numerical processing with the aid of software tools;

- Post-processing, which consists of the analysis and critical interpretation of the results.

There have been several successful cases of projects using RadiciGroup engineering polymers that have taken advantage of the valuable support of the Engineering Service: a recent example, also presented during the K fair, was a metal replacement part, the Quick SpA windlass reducer housing. Already from the early stages of the project, the Service team assisted the customer in taking into account the operational performance and any critical issues, as well as the various phenomena associated with the engineering polymer moulding process (fibre orientation, weld lines and post-moulding distortion).

To browse the Engineering Service brochure click here.