Automatic and self-cleaning filtration at constant pressure

To obtain high quality polymers from recycling processes, the filtration of the plastic melt represents one of the most important steps. For this purpose, Break Machinery has developed DUO, a dual-filter filtration system that allows maximum productivity while guaranteeing the high quality of the finished product. The geometry of the scraper disc and the innovative discharge system make it possible remove contaminants in a quick and controlled way as well as to reduce the amount of waste.

Technical features and operation

DUO is equipped with two perforated filter discs (breakers), thus increasing the filtering area and the system production capacity. Placed between the two filter discs, a rotating scraper disc incorporates blades on both sides which remove the contaminants from both filter discs. Its geometry prevents the filtered contaminants from re-entering the plastic melt. The filter surfaces are kept constantly clean, so that they can be used for longer periods than traditional systems. The laser is fundamental for the operation of DUO. The filter discs are perforated using the latest laser technologies and specially treated to resist wear, while the conical geometry of the holes facilitates the flowing of the melt.

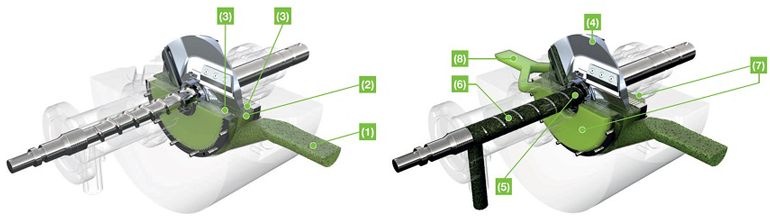

The plastic melt (1) is conveyed into the filtration chamber (2) and passes through two filters discs (3) opposed to each other. Between the two filter discs there is a scraper disc (4), equipped with interchangeable blades, which rotates and removes the contaminants from the filters by channelling them inside the scraper disc itself (5). The centre of the scraper disc is in communication with a separate discharge screw (6) that ejects the contaminants. After filtration, the melt (7) reaches the delivery channel (8) before moving on to the next process step.

General aspects and benefits

The dual filter method makes it possible to reduce the size of the filtration chamber and to increase the filtering surface available, while the operating principle of the system enables a continuous process at constant pressure. Made of high quality steel alloys and adopting anti-wear treatments for the most stressed parts, DUO is designed to guarantee high resistance to line pressures up to 350 bar. The special geometry of the six-blade rotating scraper disc ensures excellent cleaning even at low rotation speed. The contaminants are discharged via a single screw that conveys them in a single flow from both filtering surfaces. The system is designed for separating various types of highly contaminated plastics (up to 15% by weight) and handling different contaminant types such as paper, wood, aluminium, copper, etc.

The adjustable-speed discharge screw makes it possible to manage even the most contaminated materials, while maintenance and replacement operations on filters and blades can be performed without disassembling any machine part. Even maintenance operations are simple and quick and can be performed directly at the user's production plant. Continuous filtration at constant pressure maximises line productivity. The efficiency of the continuous cleaning system extends the operating life of the filters while reducing the purchase of consumables. The independent rotation of the discharge screw with respect to the scraper disc minimises waste (according to the amount of contaminants) and facilitates the treatment of highly contaminated materials.