Managing friction in dynamic seals

In order to solve the problem of friction in rubber dynamic seals, whose consequences in terms of money-loss are high, either due to maintenance or the risks of failure to operate correctly, a new consortium has been established. The SoftSlide consortium, consists of 5 international partners who have developed an innovative protocol for managing the friction coefficient, called the Friction Management Solution.

The project, funded by the EU framework programme for research and innovation Horizon 2020, involves:

- ML Engraving, an Italian company performing laser engravings to enhance functional and/or aesthetic properties of moulded parts;

- SKM Aeronautics, an Israeli company that manufactures moulds and seals;

- Reagent, an English company producing chemical additives as well as the Solgel mould release agent;

- the Institut für Dynamik und Schwingungen of the Leibniz University of Hannover, that studies the tribological properties of materials;

- the Instituto Tecnológico de Aragón, that studies texturing during moulding and the fatigue properties of materials, as well as their LCA.

The aim of the consortium will be to tackle the problem of friction on seals with tailor-made solutions, relying on technologies, machines and expertise to produce them on industrial scale.

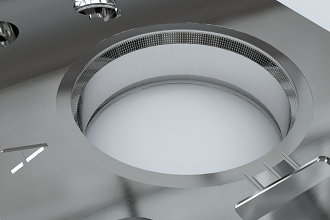

The innovation introduced by the Friction Management Solution is represented by the use of laser engraving on the mould. In order to achieve a better performance and durability of rubber seals, it is possible to create a 3D micro-texture on their surface. The technical benefits of laser texturing include the modification of the rubber contact area and the withholding of the lubricant. The Softslide consortium will focus on every aspect of friction management, from its reduction, as in the case of dynamic seals, to its increase, for example on anti-slip surfaces.

Tests and trials have confirmed a friction reduction up to 50% in working conditions, with a consequent decrease of wear, a significant increase of the seal durability and a 15% reduction of energy waste, without any specific change in lubrication conditions or in the compound. If required, friction can be increased up to 20%.

Tests and trials have confirmed a friction reduction up to 50% in working conditions, with a consequent decrease of wear, a significant increase of the seal durability and a 15% reduction of energy waste, without any specific change in lubrication conditions or in the compound. If required, friction can be increased up to 20%.

The technology developed by Softslide addresses every market where engines, dynamic equipment and automation are required such as automotive, oil & gas, wind turbines, food processing and many more.