Revolutionizing the Meat Tray Market: the Ultimate Packaging Solution

The meat tray market, specifically MAP trays (used for "Meat and Poultry"), has traditionally relied on various packaging solutions, including EPS, PP, and PET trays, often sealed or wrapped with film. However, as the industry shifts towards sustainable solutions, the demand for mono PET trays has grown. WM Thermoforming Machines is leading this change by integrating into their FC/FX steel rule die thermoforming range innovative technology that not only enhances the recyclability of these trays but also optimizes the overall production process.

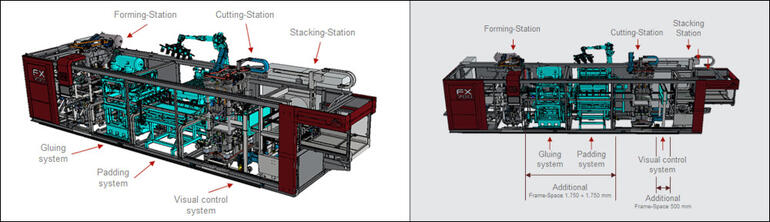

WM is set to deliver in November a complete thermoforming machine that integrates a gluing system, a padding system, and AUSIL’s AI-driven automated Inspection System.

The gluing system significantly improves weldability without the need for PE laminates. This innovation not only addresses recyclability challenges but also maintains product integrity, reducing environmental impact. Additionally, the padding station that integrates liquid-absorbing padding is a crucial feature for sectors such as the meat industry, ensuring hygienic and practical packaging solutions.

Generally speaking, when it comes to integrating these technologies, manufacturers have two options: off-line and in-line applications. In-line integration is designed for high productivity, minimizing space requirements and manual handling while maintaining a continuous production process. This streamlined approach results in better hygiene, improved quality control, and overall higher efficiency. On the other hand, off-line integration offers greater flexibility, allowing for smaller production runs and easier adjustments.

The gluing technology available on WM’s machines offers several advantages over traditional PET/PE tray solutions. First, the material is fully recyclable, unlike standard laminated MAP trays. Second, the glue is applied at a lower temperature, which treats the PET more gently, preserving its quality. Lastly, the subsequent welding time is reduced, resulting in in faster production speeds and significant energy savings, and making WM’s systems an attractive choice for eco-conscious manufacturers seeking to improve both efficiency and sustainability.

When integrating multiple processes like gluing and padding, having an advanced inspection system is fundamental for maintaining optimal quality. To address this need, WM offers the option to equip machines with the AUSIL AI automated Inspection System. This sophisticated system monitors and controls key aspects of production, ensuring tray conformity, verifying precise glue distribution, and confirming accurate pad placement. By playing a crucial role in quality control, the vision system offers manufacturers peace of mind, guaranteeing that every tray meets the highest standards and exact specifications.

By combining cutting-edge technology, efficiency, and sustainability, WM Thermoforming Machines is setting a new benchmark in the meat tray market, providing manufacturers with a complete, integrated solution for the future of packaging.

For those interested in learning more about WM’s innovative solutions for the meat tray market, including integrated gluing, padding, and inspection system, feel free to reach out to WM Thermoforming Machines. WM team is ready to provide further information and support, helping manufacturers enhance both productivity and sustainability in their packaging processes.

Contact us at [email protected]

Subscribe to our Newsletter or follow us on Youtube or Linkedin to receive the latest news and updates