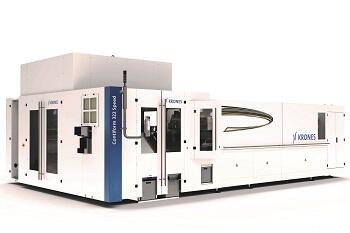

The hundredth Contiform 3 Speed for stretch blow-moulding has been installed

Less than two years later its launch, Krones recently installed at Odenwald Quelle, a manufacturer of bottles for soft drinks based in Heppenheim (Germany), the hundredth Contiform 3 Speed machine for the stretch-blow molding of bottles in PET. “The Contiform 3 Speed boasts several persuasively attractive pluses. It is compactly dimensioned and produces more containers while consumption levels are lower. And it also effortlessly handles preforms made of rPET. This advantage was of crucial importance to us because we’ve since 2020 been selling only plastic bottles made of 100 per cent recyclate”, Andreas Schmidt, managing partner at Odenwald Quelle, stated.

Whereas in the case of conventional stretch blow-moulders, a pressure pad in the mould carrier additionally keeps the two halves of the mould together during the stretch blow-moulding process, the Contiform 3 Speed has been designed in such a way that the two halves are kept together purely by means of the revamped mould carrier locking mechanism. The omission of the pressure pad means that the moulds can produce bottles with a volume of up to two litres - and this in a blow-module size so far used in the small-cavity machines, which is on average 22% smaller than the comparable blow module of the Contiform 3 Pro. But eliminating the pressure pad provides advantages not only in terms of line layout but also in regard to media and energy consumption: it makes for savings of up to 15% of highly compressed air in comparison to all other stretch blow-moulders currently available on the market.