TPE with EPDM adhesion properties for automotive applications

Kraiburg TPE is launching new EPDM adhesion compounds designed for the automotive sealing and exterior sector, addressing global requirements and needs with particular focus on the markets in Europe, North, South and Central America.

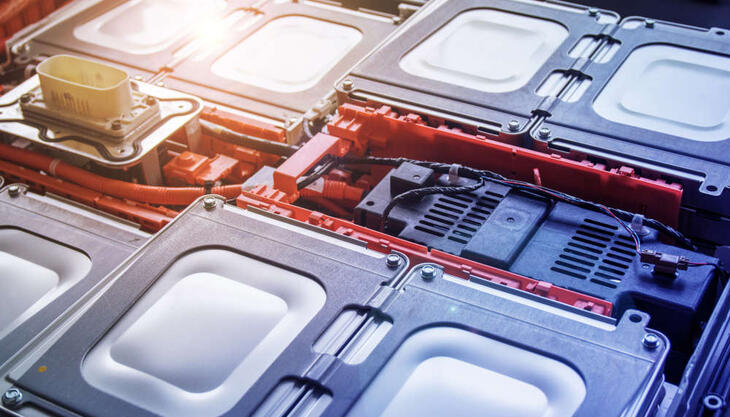

These compounds epitomize a remarkable leap in material technology, delivering adhesion, durability, and processability essential for demanding applications. Specifically formulated for automotive exterior parts with UV resistance, they find application in glass run channels and sealing profiles featuring moulded corner joints and end caps.

Kraiburg TPE’s latest market introduction features constant EPDM adhesion quality proven at 23°C and 90°C heat aging, with dry surface appearance. The optimized flow properties provide a broad processing window and increased design flexibility in part and tool design while maintaining high performance standards. Additionally, the compounds offer weathering resistance, colour stability, low surface friction behaviour and wear and tear resistance. The homogeneous surface quality enhances aesthetics and functionality, meeting the stringent requirements of automotive applications.

Compared to full EPDM sealing solutions, TPE-EPDM hybrid technology meets market trends by supporting the transition to TPE for sealing systems due to process efficiency. A lower product carbon footprint as well as weight reduction support efforts towards sustainability.