For three years towards a more sustainable and circular chemistry

At the recent pre-K conference organised by EMG in Rotterdam, Ineos – three years on from the symbolic launch of its “Footprint Town” initiative – presented an update on its journey towards a more sustainable and circular chemicals industry.

The event, introduced by Yvonne van Veen, Head of Sustainability, and Sven Riechers, Head of Sales, highlighted the company’s advances in implementing a strategy that blends technological innovation, industrial investment, and regulatory alignment to reduce the environmental impact of styrenic materials without compromising performance.

The presentation began by reaffirming the company’s core values: Grit and Humour. The former reflects a commitment to resilience, operational excellence, and safety, while the latter expresses a positive, solution-oriented attitude in the face of market challenges – rooted in the belief that no problem is insurmountable.

“We’ve moved from Footprint Town to a fully-fledged industrial roadmap, with key milestones already achieved and others in progress,” said van Veen. With a portfolio of over 2,000 materials and annual revenues of around 5 billion euros, INEOS serves key sectors including packaging, automotive, appliances, toys, and medical. Styrenics are part of everyday life – from yoghurt pots to car dashboards.

At the heart of Ineos’ sustainability strategy is mechanical recycling, still considered the most environmentally favourable option in terms of carbon footprint. One tangible result is the first mechanically recycled polystyrene yoghurt pot for food contact, now available in Lidl supermarkets in Germany, developed in line with new EU rules on innovative recycling technologies.

Alongside this, chemical recycling via depolymerisation is also under development, in collaboration with partners such as Endeavour, which operates a working post-consumer waste processing plant. The recycled feedstocks are converted into PS, ABS and SBC at INEOS production sites – including Antwerp – and are fully drop-in compatible, requiring no changes to existing processes.

Significant attention was also given to bio-attribution – a certified technology (ISCC+) allowing fossil-equivalent materials to be produced from renewable feedstocks like used cooking oil or woody biomass. Examples include a partnership with Playmobil using bio-attributed ABS, and further applications in medical devices and fresh food packaging, such as those developed with Tönnies Group.

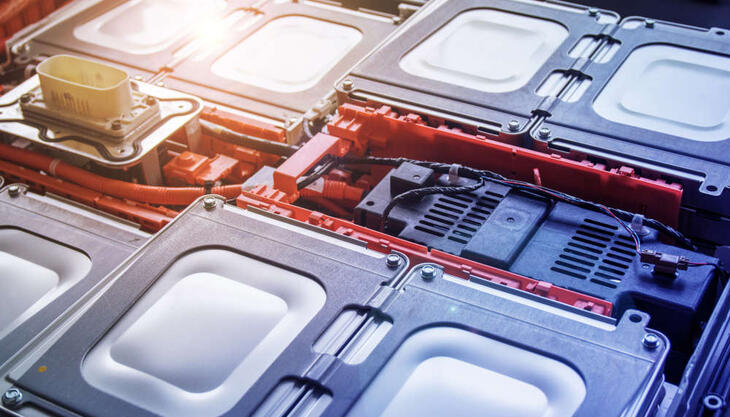

Ineos’ sustainable materials cover a broad spectrum of applications. In the automotive sector, new grades have been developed for interior parts, including rear lamp housing, meeting both aesthetic and thermal requirements. In construction and home appliances, recycled content is being incorporated into technically demanding formulations, supported by ongoing composite research. Also noteworthy is the collaboration with Grohe, which selected a material containing 50% circular content for use in galvanic applications – showing that even technical sectors can adopt low-impact plastics without compromising on quality or performance.

Supporting its roadmap, INEOS is investing in major industrial projects including Project One – a new, low-carbon cracker under construction in Antwerp – and Greensand, a CO2 capture and storage initiative.

The goal is to drastically reduce the climate footprint through more efficient processes, innovative materials, and the use of green energy. As highlighted during the presentation, INEOS has already achieved a reduction of over one million tonnes of CO2 within just a few years.

Another key element of the strategy is also providing customers with support in assessing the carbon footprint of the materials they use, through a “cradle-to-gate” calculation system that enables easy integration of data into sustainability reports. An internal database has been developed, accessible to clients, offering detailed insights into the environmental impact of each product – for instance, to calculate the footprint of a bio-attributed ABS.

Collection and recycling initiatives are rapidly expanding in Belgium, Germany, and France, and the company is actively participating in European consortium such as PS25 in France and Circular Solutions, which now also has a branch in the United States. Despite regulatory differences between Europe and North America, the company has launched similar projects overseas, with a particular focus on progressive states such as California.