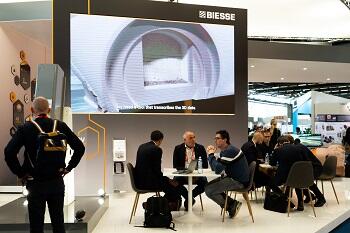

Biesse at JEC World between innovations and trends for plastics and composites

Biesse participation in JEC World (Paris, May 3-5) took place in the name of innovation and the latest trends in the field of plastic and composite materials processing. The company presented the benefits offered by HSD Mechatronics technologies, a brand specialized in the production of electro-spindles, milling heads and components for processing composite materials, metal and more.

Biesse solutions are extremely precise, easy to use and versatile, and come with all the optional features that are needed in order to process the materials that are on the market today. Biesse has created a range of products made up of panel saws (Selco Plast), work centres (Rover Plast and Materia), waterjet cutting systems (Primus), sanders (Viet Plast), and thermoformers (Terma).

“Our strength lies in the fact that we offer the customer a complete machining process, from sectioning to factory automation. With our technologies and expertise, we are dedicated to the plastics and composite markets, courtesy of our numerous partnerships in the automotive, aerospace and industrial components sectors”, explained Guillaume Thenon, Biesse Business Development Manager Plastic and Composite Materials.

“Our strength lies in the fact that we offer the customer a complete machining process, from sectioning to factory automation. With our technologies and expertise, we are dedicated to the plastics and composite markets, courtesy of our numerous partnerships in the automotive, aerospace and industrial components sectors”, explained Guillaume Thenon, Biesse Business Development Manager Plastic and Composite Materials.

In cooperation with Factory Unit and L2Concept, specialized in automotive industrial design, Biesse also presented a "concept car" made with the use of its technologies, which visitors were able to virtually drive through a simulator, participating in the Biesse Race.

“The partnership between Biesse and Factory Unit began a few years ago, when Alain Grandjean, CEO and founder of Factory Unit, was looking for a machining centre that could meet the high expectations associated with the design and implementation of projects like this. The collaborative relationship between the two companies has enabled mutual growth thanks to the exchange of skills, knowledge and technologies”, explained Silvano Maddalon, Biesse Sales Manager Plastic and Composite Materials.