Testing plastics from static to dynamic, from R&D to the continue use

At K2016, Instron, a leading global manufacturer of material and structural testing systems, will present their comprehensive portfolio of systems for testing polymers from static to dynamic, from R&D to 24/7.

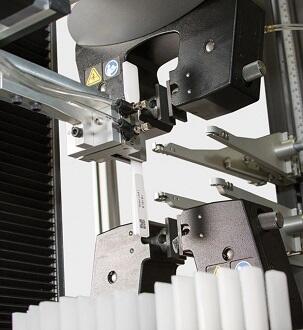

For static tensile, flexure, compression, bend, peel, shear, tear and cyclic tests, Instron will show a versatile 5969 electromechanical dual column table-top system for mid-range testing, together with pneumatic grips, designed for a nominal load of 10 kN, in combination with an automatically contacting Instron AutoX extensometer. For automated testing runs, meeting the requirements of all common testing standards, Instron will present their latest development, the TestMaster AT3 for tensile and flexure testing. Once the tray has been loaded and the start button pushed, its automated specimen loading feature improves repeatability and reproducibility of testing and results, minimising human influence, increasing safety by keeping the operator away from the testing area, and improving ergonomics by virtually eliminating repetitive motions associated with high volume manual testing. All test runs will be controlled, documented and stored in a database using Instron’s universal Bluehill 3 testing software with fully-integrated modular software packages that provide easy, tailored application solutions for today's laboratory managers and test technicians.

For impact

testing of polymers, Instron will exhibit two systems: a Ceast 9350 floor

standing drop tower designed to deliver 0.59 to 757 J or up to 1,800 J together

with an environmental chamber, and a motorised Ceast 9050 impact pendulum. Both

systems will be operated using Instron’s Ceast VisualImpact software, designed

to control these devices, record force and absorbed energy data, visualise and

help analyse the results and calculate resilience. VisualImpact is tailored to

using the Ceast high-speed data acquisition system DAS64K. Providing a data

acquisition rate of 4 MHz, this system is particularly advantageous when

testing brittle materials or performing tests at high speeds or low

temperatures, as will be showcased on the stand.

For impact

testing of polymers, Instron will exhibit two systems: a Ceast 9350 floor

standing drop tower designed to deliver 0.59 to 757 J or up to 1,800 J together

with an environmental chamber, and a motorised Ceast 9050 impact pendulum. Both

systems will be operated using Instron’s Ceast VisualImpact software, designed

to control these devices, record force and absorbed energy data, visualise and

help analyse the results and calculate resilience. VisualImpact is tailored to

using the Ceast high-speed data acquisition system DAS64K. Providing a data

acquisition rate of 4 MHz, this system is particularly advantageous when

testing brittle materials or performing tests at high speeds or low

temperatures, as will be showcased on the stand.

For HDT and Vicat tests, Instron will present its recently introduced Instron HV Series designed to significantly reduce workload and increase efficiency in the testing lab. Available for visitors will be a HV6X with six testing stations and automatic weights application, using advanced electronics that automatically zero the position of the LVDT measuring sensors before starting a test, reducing test time and human errors. The HV tester will be operated by the company’s Bluehill HV test software to run tests, edit methods, analyse results or configure the system with a few mouse clicks, even further minimising effort, and raising both laboratory efficiency and throughput to a high level.

For dynamic

testing tasks, Instron will showcase at K2016 the ElectroPuls E1000 Electrodynamic

Testing System which uses patented, oil-free linear motor technology, together

with the recently introduced AVE2 Advanced Video Extensometer. Offering

slow-speed static and high-frequency fatigue testing, the versatile ElectroPuls

systems are ideal for any lab or office space, designed for up to 10 kN axial

load or combined axial-torsion loadings, delivering 10 kN and 100 Nm. The AVE2

is a non-contacting extensometer for dynamic strain control at variable gauge

lengths and differing travels, offering speed and flexibility for studying the

behaviour of materials without damaging the specimen's surface. A

fully-integrated device, it easily adapts to the normal fluctuations in

environmental conditions in the lab. Designed to dramatically reduce errors from

thermal and lighting variations that are common in most labs, the AVE2 utilises

a real-time 490 Hz data rate while achieving a one micron accuracy.

For dynamic

testing tasks, Instron will showcase at K2016 the ElectroPuls E1000 Electrodynamic

Testing System which uses patented, oil-free linear motor technology, together

with the recently introduced AVE2 Advanced Video Extensometer. Offering

slow-speed static and high-frequency fatigue testing, the versatile ElectroPuls

systems are ideal for any lab or office space, designed for up to 10 kN axial

load or combined axial-torsion loadings, delivering 10 kN and 100 Nm. The AVE2

is a non-contacting extensometer for dynamic strain control at variable gauge

lengths and differing travels, offering speed and flexibility for studying the

behaviour of materials without damaging the specimen's surface. A

fully-integrated device, it easily adapts to the normal fluctuations in

environmental conditions in the lab. Designed to dramatically reduce errors from

thermal and lighting variations that are common in most labs, the AVE2 utilises

a real-time 490 Hz data rate while achieving a one micron accuracy.