"Campetella Robotic Calling": 30 days of open house on IML technology

Starting from October 1, “Campetella Robotic Calling” is a 30-day open house organized by Campetella Robotic Center at its headquarters in Montecassiano (Macerata, Italy) to present latest generation robots and autonomous mobile robots (AMR) for increasing performances of its IML technology. Two special applications, which comply with the Industry 4.0, will attract the interest of visitors for the whole event.

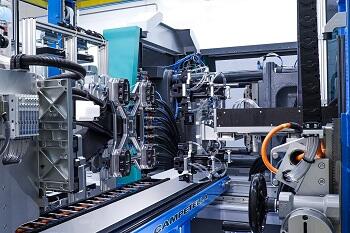

An X-Series Mini-Modula compact side-entry robot from Campetella will be used for the IML of plastic yoghurt cups made of polypropylene. The robot will be equipped with a quick and compact horizontal arm, responsible for very fast label inserting and product take-out operations. A tilting axis will guarantee a hygienic process, which will end with the cups being stacked upside down with their openings on the conveyor belt. An additional advantage of the Mini-Modula consists in its extremely small footprint. It will cooperate with the new X-Series CO1 Cartesian robot. Its electric servo axis is the right hand to move the stacks of cups from the conveyor to a storage box. An Omron AMR will take care of transporting the boxes to the finished goods warehouse. Full to the warehouse, empty back to the belt. The entire system will be a four-cavity application with a total cycle time of no more than 2.0 seconds. The IMM interlock time will be of only 0.6 seconds. The two Campetella robots will work hand in hand, thereby serving an Arburg Allrounder 570 H hybrid injection moulding machine with a clamping force of 1800 kN, and the inherent four-cavity mould from Simon respectively. The Italian label manufacturer Viappiani will be responsible for the "L" label in the IML.

As for the second application, an X-Series Modula high-speed side-entry robot will be used for labelling plastic cheese spread tubs in a Bazigos four-cavity mould. Four Mevisco cameras will monitor the product quality inline and continuously. A very fast label feeder with servo drive will be used on the robot, which manages the 5-sided Viappiani labels. Here again, the tilting axis will perform hygienic upside down stacking of the tubs on the conveyor belt. With its high payload, an X-Series Spin3 Scara robot will grip the labelled stacks and quickly will deposit them in a transport box. Finally, another Omron AMR will be in charge of storing the boxes in the warehouse. The entire automation system will be used on an Arburg 630 H hybrid injection moulding machine with a clamping force of 2300 kN. Labelling takes place within a 4-second cycle and/or an IMM interlock time of only 0.9 seconds. The polypropylene raw material treatment will be carried out by Moretto ancillary equipment and centralized cooling systems.

As for the second application, an X-Series Modula high-speed side-entry robot will be used for labelling plastic cheese spread tubs in a Bazigos four-cavity mould. Four Mevisco cameras will monitor the product quality inline and continuously. A very fast label feeder with servo drive will be used on the robot, which manages the 5-sided Viappiani labels. Here again, the tilting axis will perform hygienic upside down stacking of the tubs on the conveyor belt. With its high payload, an X-Series Spin3 Scara robot will grip the labelled stacks and quickly will deposit them in a transport box. Finally, another Omron AMR will be in charge of storing the boxes in the warehouse. The entire automation system will be used on an Arburg 630 H hybrid injection moulding machine with a clamping force of 2300 kN. Labelling takes place within a 4-second cycle and/or an IMM interlock time of only 0.9 seconds. The polypropylene raw material treatment will be carried out by Moretto ancillary equipment and centralized cooling systems.

Campetella has designed the robot components in lightweight construction by making use of special materials originating from the aerospace industry or the competition vehicle sector. The robots are characterized by precision, reliability, robustness, permanent load capacity and operational speed. "We have spent the past months bringing new robot developments to series production readiness. The focus is on precision, speed, versatility, reliability, application-specific programmability and safety", Elia Campetella explained.

The first "Campetella Calling" day will begin with a 25-minute multimedia presentation about the company, its teams of experts, its know how in the field of automation. For safety reasons, the 40 visitors per day will divided into the smallest possible groups. They will thus take part to a guided tour through the design, assembly and test departments, further to have a look of the two IML systems in operation. "Safety first. This is an indispensable part of the 30 Campetella Calling days: 40 registered guests per day, obligatory masks, social distancing, reserved seats and more - to protect our guests and our own teams", Marco Marconi, area sales manager, concluded.

The first "Campetella Calling" day will begin with a 25-minute multimedia presentation about the company, its teams of experts, its know how in the field of automation. For safety reasons, the 40 visitors per day will divided into the smallest possible groups. They will thus take part to a guided tour through the design, assembly and test departments, further to have a look of the two IML systems in operation. "Safety first. This is an indispensable part of the 30 Campetella Calling days: 40 registered guests per day, obligatory masks, social distancing, reserved seats and more - to protect our guests and our own teams", Marco Marconi, area sales manager, concluded.