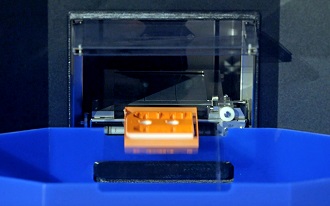

Modular cells for the 3D printing

Stratasys, the 3D printing and additive manufacturing solutions company, took a significant step into low-volume, continuous production using additive technology today when it unveiled a new product under development - the Stratasys Continuous Build 3D Demonstrator - at the Rapid + TCT show in Pittsburgh (May 8-11). Commercial product availability has not yet been announced.

The new platform is composed of a modular unit with multiple 3D print cells working simultaneously and driven by a central, cloud-based architecture. To set new standards in additive manufacturing throughput, the Stratasys Continuous Build 3D Demonstrator is designed to produce parts in a continuous stream with only minor operator intervention, automatically ejecting completed parts and commencing new ones.

Each 3D print cell can produce a different job to help enable mass customization projects. Additional cells can be added at any time to the scalable platform to increase production capacity as demand requires. Automatic queue management, load balancing and architecture redundancy further lead to accelerated throughput as jobs are automatically routed to available print cells. If a single print cell fails, the job will be automatically rerouted to the next available cell.

Target applications include education RP labs and environments that can benefit from zero tooling production and from a zero inventory supply chain.

“The

Stratasys Continuous Build 3D Demonstrator is an important milestone in the

company’s long term vision to make additive manufacturing a viable solution for

volume production environments”, says Scott Crump, Stratasys cofounder and CIO.

“It combines our FDM print quality, GrabCAD control and monitoring, and a new

multi-cell, scalable architecture to create a breakthrough manufacturing

platform”.

“The

Stratasys Continuous Build 3D Demonstrator is an important milestone in the

company’s long term vision to make additive manufacturing a viable solution for

volume production environments”, says Scott Crump, Stratasys cofounder and CIO.

“It combines our FDM print quality, GrabCAD control and monitoring, and a new

multi-cell, scalable architecture to create a breakthrough manufacturing

platform”.

A variety of Stratasys customers, including designers and manufacturers, have begun using the Continuous Build 3D Demonstrator to enhance their offerings and explore new business opportunities. These include:

- Savannah College of Art and Design (Scad), a preeminent art and design university, ensures all students have 24/7 access to state of the art 3D printing services; installing a Stratasys Continuous Build 3D Demonstrator in the award-winning university’s Design Lab expands student learning opportunities in 3D printing, and the enhanced technological capacities benefit professors and students focused on advanced design projects and skills; “This is the future!” said Scad president and founder Paula Wallace. “We believe the Stratasys Continuous Build 3D Demonstrator represents the next generation of 3D printing, the first-ever platform of its kind. The world has never seen an approach to rapid prototyping like this before. As ever, Scad students are the earliest adopters of design technology”.

- In’Tech Industries, a premiere supplier of rapid prototyping/additive manufacturing, engineering services, tooling services and injection mouding, wanted to expand its 3D printing offerings to create a bridge-to-production solution for their OEM customers; the automated workflow of the Stratasys Continuous Build 3D Demonstrator enabled In’Tech to offer same-day or next-day delivery of quantities of identical or mixed parts that would eventually be injection moulded, helping the company dramatically improve customer service without adding additional staff.

- Fathom, an advanced manufacturer with an expertise in additive technologies, is leveraging the Continuous Build 3D Demonstrator to push the limits of additive manufacturing; many of its customers have adopted digital fabrication beyond prototyping as a means of production and are using proven additive technologies like FDM for high-value, end-use applications. Having a six-cell configuration in-house at Fathom increases throughput significantly and enables a greater volume of FDM parts within a shorter lead-time; with the Continuous Build 3D Demonstrator, there is an opportunity to use FDM more effectively for not just a hundred just-in-time parts, but for 1,000+ parts on-demand.