First time in Germany

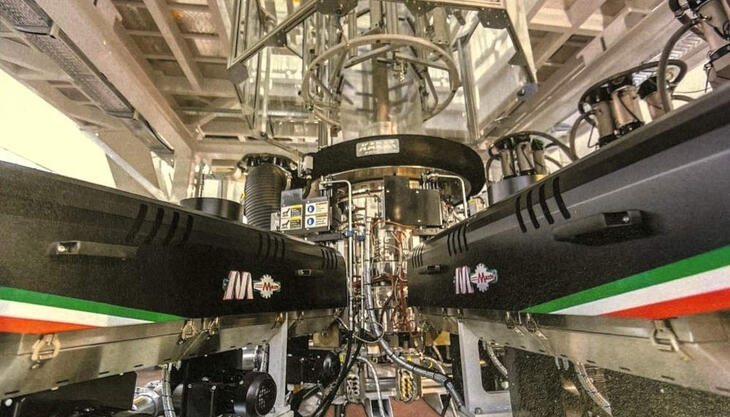

The first 9-layer coextrusion line by Macchi in Germany has recently been delivered and installed at the premises of Duoplast, a leading producer of agricultural film. The line - configured with seven 55-mm extruders, two 65-mm extruders, a 500-mm die head and a BO Plus double station automatic winder - has a capacity of about 500 kg/h.

The line is designed for new products development in the agricultural field, load security stretch film applications and food barrier films, and will enable Duoplast to produce stretch films with even more efficiency, thinner layers and higher stretchability. The new line extends Duoplast’s portfolio of high-performance films based on recycled material and on polymers from renewable raw materials.

Furthermore,

the line incorporates many of the most recent Macchi's technological

developments, such as, in particular: an air recirculation system for a dramatic

reduction in energy consumption; a micro porous inversion bar system for the specific

production of sticky films; a fully automated system for unloading finished

rolls; the "Macchi 4.0" system for production data exchange

Furthermore,

the line incorporates many of the most recent Macchi's technological

developments, such as, in particular: an air recirculation system for a dramatic

reduction in energy consumption; a micro porous inversion bar system for the specific

production of sticky films; a fully automated system for unloading finished

rolls; the "Macchi 4.0" system for production data exchange