Coperion at K 2022 focuses on compounding and recycling

At K 2022 (Düsseldorf, October 19-26), Coperion and Coperion K-Tron will be presenting a variety of new and ongoing developments that will markedly increase the efficiency of plastics compounding processes, help boost conscientious resource handling while at the same time achieving very high product quality. Coperion will be exhibiting an entire production line for recycling polyethylene terephthalate (PET) at their booth within the VDMA’s Circular Economy Forum, a pavilion on the open-air fairgrounds.

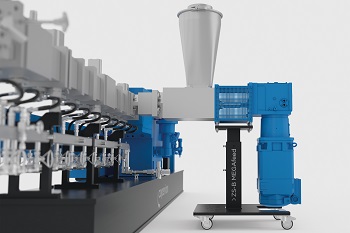

One eye catcher at the Coperion booth will be the high performance ZSK Mc18 extruder with a 70 mm screw diameter. With its high specific torque of 18 Nm/cm3, it is especially suited for efficient compounding of plastics at very high throughput rates and with comparatively low energy consumption. The ZSK extruder is equipped with a ZS-B easy side feeder as well as a ZS-EG side devolatilization unit. Both the ZS-B as well as the ZS-EG - thanks to their simple design - significantly reduce the time needed for recipe changes or maintenance tasks, since they can easily be removed from the process section in just a few steps. A K3-ML-D5-V200 vibratory feeder from Coperion K-Tron will be on display at the main intake of the ZSK 70 Mc18. The ZS-B easy will be equipped with a K-ML-SFS-BSP-100 Bulk Solids Pump (BSP) feeder.

Another highlight at the Coperion booth will be the STS Mc11 series laboratory extruder with a 25 mm screw diameter. It stands out with its simple design, user friendliness and easy cleaning. The STS 25 Mc11 will be exhibited with a Coperion K-Tron K-ML-SFS-KT20 twin screw feeder. Moreover, the new, preconfigured ProRate Plus feeder line will be available to view in all three available sizes: small, medium, and large. This continuous gravimetric feeder from Coperion K-Tron is very robust and is an economical solution for reliable feeding of free-flowing bulk materials.

The SP series dual bearing strand pelletizers have been given a comprehensive facelift; Coperion’s SP340 model will represent this development at the K booth. In comparison to the previous model, the new SP strand pelletizer allows even faster recipe and colour changes. The cutting chamber works with absolutely no dead space; thanks to its quick-release function, the cutting unit can be swapped out quickly and easily. The pelletizer’s interior has improved accessibility and is very easy to clean. One further highlight of Coperion’s showing at K 2022 will be the ZXQ 800 rotary valve. This high-performance valve, which works with especially low gas leakage, was developed by Coperion especially for powder intake into pneumatic conveying lines at up to 3.5 bar. Thanks to its enormous capacity, it is very well suited for systems planned for polyolefin manufacturing in the future.

Coperion will present its combined process solutions and technologies for the economical recycling of various plastics while achieving the highest levels of product quality. At the centre will be a system built around a ZSK 58 Mc18 twin screw extruder configured for manufacturing high-quality PET using recycled materials. For feeding voluminous flakes and fibres (PET and other plastics) efficiently into the ZSK twin screw extruder, Coperion will show the SWB-300 Smart Weigh Belt Feeder with a S100 single screw pre-feeder, as well as the new ZS-B 70 MEGAfeed side feeder. Using the innovative, newly developed Coperion ZS-B MEGAfeed, plastic recyclate with a bulk density under 200 kg/m³, long considered intake-limited and thus not worth recycling, can be reliably fed in large quantities into smaller sizes of Coperion’s ZSK twin screw extruders and be concurrently recycled and compounded.

Coperion will present its combined process solutions and technologies for the economical recycling of various plastics while achieving the highest levels of product quality. At the centre will be a system built around a ZSK 58 Mc18 twin screw extruder configured for manufacturing high-quality PET using recycled materials. For feeding voluminous flakes and fibres (PET and other plastics) efficiently into the ZSK twin screw extruder, Coperion will show the SWB-300 Smart Weigh Belt Feeder with a S100 single screw pre-feeder, as well as the new ZS-B 70 MEGAfeed side feeder. Using the innovative, newly developed Coperion ZS-B MEGAfeed, plastic recyclate with a bulk density under 200 kg/m³, long considered intake-limited and thus not worth recycling, can be reliably fed in large quantities into smaller sizes of Coperion’s ZSK twin screw extruders and be concurrently recycled and compounded.

Melting, intensive devolatilization, and complete homogenization take place in the process section of the ZSK 58 Mc18, before the material stream is transferred via a gear pump and filter with an automatic screen pack changer to an underwater pelletizer for pellet production. Finally, the pellets are condensed in the SSP (Solid State Polycondensation) reactor and can then be processed again into bottles, fibres, or films. Thanks to the ZSK’s very good devolatilization properties, volatile components such as monomers, oligomers and water are reliably removed. Savings in operating and logistics costs as well as reduced energy consumption are further advantages of Coperion systems for recycling PET.

If the plastic pellets produced create undesirable odours, these can be reliably removed using deodorization equipment from Coperion. In order to optimize such deodorizing equipment’s specification and to individually determine its operational parameters, Coperion now provides onsite tests using a mobile unit for reducing plastic pellet and recyclate odour at customers’ production facilities. Using this solution with freshly produced product and under actual production conditions, the possibilities for reducing recyclate odour can be thoroughly investigated, and system parameters to achieve desired product quality can be defined on location. Coperion will exhibit this mobile deodorization unit in its Recycling Pavilion.