WM’s Portfolio: Advanced Thermoforming Technology with Seamless Mold Matching

Why mould matching matters

In the thermoforming industry, the tooling represents one of the most critical assets. It’s not just the financial investment, but also the precision and machine specific customization of these tools to ensure the needed specific production needs. Losing the ability to use existing tooling when opting a new machine manufacturer can lead to significant additional costs and a long learning curve for the operators. That’s why WM’s almost complete product portfolio is now offering mould matching for most of its tilting and steel rule machines.

Plug-and-Play mould matching

WM’s FX, FLEX and Twist series are engineered to integrate seamlessly the tooling of a number of U.S. and European machine manufacturers. Whether you currently are using Illig, Kiefel, or Sencorp, our machines offer a “plug-and-play” solution that minimizes the need for major tool modifications. Our adaptation plates provide a cost-effective solution and optimal functionality of your existing tooling. Our design philosophy allows your company to use your existing production tooling while upgrading to a new technology offering superior performance, reliability, and efficiency.

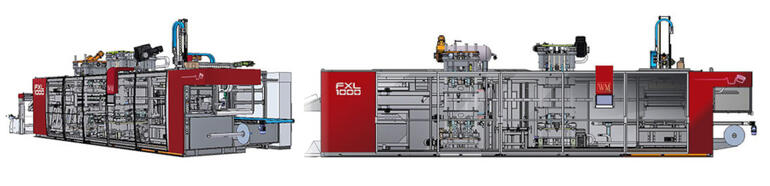

Introducing the FXL1000: tailored for the US market

One of WM’s latest innovations, the FXL1000, is specifically designed to meet the unique demands of the U.S. market. This machine, a larger sibling to our successful FC1000 E, is built to compete directly with popular models like the KMD 90 and Sencorp 2500. The FXL1000 boasts a larger forming area (1060 x 940 mm), higher forming force (67 US Tons), and a robust four-column forming press that delivers the highest clamping force and cycle speed in its class—up to 22% faster than competitors like the KMD 90, and offers the highest throughput per sqm available on the market.

Additionally, the FXL1000 features a lateral mould loading system for easier handling and a lateral take-off robot system that enhances ergonomic comfort during product packing. With a forming depth of 160 mm and a cutting force of 118 US Tons, the FXL1000 ensures that your production lines can handle even the most demanding tasks with ease. This combination of features makes the FXL1000 an ideal choice for U.S. manufacturers looking to upgrade their thermoforming equipment while maintaining tooling compatibility and maximizing production efficiency.

The WM thermoforming machine Advantage

Beyond compatibility, WM’s machines are designed with a host of features that set them apart from the competition. These include:

- Ultra-Robust Equipment: Built to last and withstand the rigors of high-volume production, WM machines offer unparalleled durability;

- Highest throughput per square meter: Our machines ensure maximum performance, allowing you to make the most of your production space;

- Highly Intuitive Software: WM’s refined mechanics and user-friendly software maximize machine reliability, reduce setup times, and optimize operations;

- Data-Driven Technology: Our machines feature advanced analytics and data collection, allowing for easier machine setup and more efficient production management;

- Personalized Customer Service: WM is committed to providing top-notch support, ensuring that your transition to our machines is as smooth as possible;

- Differentiated Integrated Automation: From multi-stacker systems to AI-powered vision inspection, WM offers integrated automation solutions that enhance your production capabilities;

- My FX App: Monitor and manage your WM machine fleet from anywhere with our convenient app, designed to give you complete control over your operations.

Upgrade with confidence

At WM, we understand that changing your thermoforming equipment is a significant decision. That’s why we’ve engineered our machines to offer the perfect blend of innovation, compatibility, and performance. With our Plug-and-Play systems, you can transition to WM technology without losing the value of your existing tooling, ensuring that your production remains efficient, cost-effective, and ahead of the curve.

If you’re ready to upgrade your thermoforming equipment or simply want to explore your options, our sales managers are here to help you find the best solution for your needs. Contact us today to learn more about how WM Thermoforming Machines can enhance your production and support your business’s growth.

Contact us at [email protected]

Subscribe to our Newsletter or follow us on Youtube or Linkedin to receive the latest news and updates.