PA pipes for the automotive industry

For the production of multi-layer pipes complying with the Euro II/V standards for the handling of fuel and hydraulic oil in motor vehicles, Amut offers single-screw extrusion lines equipped with a gravimetric system ensuring precise control of the weight per linear metre as well as constant thickness of the various layers making up the pipe. The pipe can incorporate up to five layers: the outer and inner ones are functional layers, made from conductive PA 12 for example, while the core ones, made from EVOH, PBT or fluoropolymer with adhesive material in between, create the barrier effect. For the processing of fluoropolymer resins, the screw and the barrel of the plasticisation unit are made from alloys containing a high percentage of nickel, in order to guarantee a high resistance to abrasion and corrosion. The new geometry of the feed bushings, which are grooved (and, when necessary, water cooled), coupled with the new-generation plasticising screws, guarantee high output rates, consistent melt quality and low energy consumption (kW/kg).

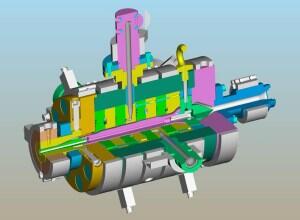

The coextrusion head has a tapering spiral design and, if necessary, can be made from high-performance corrosion-resistant materials such as Inconel or Hastelloy. Thanks to the special geometry of the head, the distribution of the thickness of the individual layers is not influenced by variations in the viscosity of the polymer, thereby helping to minimise control interventions by the operator. The head is also available in a version for the production of multi-layer corrugated pipes which allows the wall thickness to be aligned by adjusting the central core while the die remains aligned with the corrugator moulds.

The limited friction of the extrudate in this sizing die of the new generation makes it possible to reduce the tension stress on the pipe and increase the extrusion speed, which when producing 5-layer pipes can reach 60-70 m/min. Openable sizing dies are used for particularly small pipes, so as to facilitate the line start-up procedures. Given the considerable sizing speed, the longer vacuum section results in an improved control of the pipe's external geometry. The vacuum can be varied automatically thanks to a system that connects the pipe's O.D. laser control with an electronic control valve. This valve adjusts the vacuum inside the tank, keeping the outer diameter constant even at extremely high extrusion speeds. The internal water temperature is automatically controlled by means of a thermostatic valve.

Equipped with tracks with a maximum length of 600 mm and a feedback type servomotor (with encoder for speed control), the haul-off guarantees constant extrusion speeds even when operating at 100 m/min. Given the high extrusion speed, this line is offered with an automatic winding system which allows the user to set various coil lengths directly from the operator's panel. The pipe cutting and coil change phases are also fully automatic.