Three days dedicated to engineering material processing

An event by Biesse dedicated to processing technologies for advanced materials, Inside comes back at the Biesse Group Pesaro Campus from October 3 to 5. This year too, the event will put together the experience of a large industrial group, the strength of a global distribution network, and the expertise of a team that combines research and innovation.

For fifty years, Biesse has been providing state-of-the-art solutions designed for the processing of engineering materials to create reliable, accurate and high-quality end products destined for various industrial sectors: automotive, aerospace, nautical, energy, etc.

"Inside Biesse attracts visitors from all over the world and offers them the opportunity to live the Biesse experience in all its facets and to understand our passion, our knowledge and our technology, turning these aspects into competitive advantages that permit our customers to emerge in today's complex market", said Raphaël Prati, marketing and communication manager at Biesse Group.

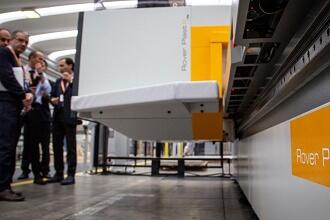

At Inside, many technologies will be demonstrated live. For instance, the Rover Plast B FT, a numerical-control work cell with a gantry frame and an FT table for plastics and composites nesting, and Materia CL, a 5-axis solution with a mobile bridge architecture, designed and built for the high-speed processing of advanced materials.

The Selco Plast WN 7 is the top-of-the-range panel sizing machine designed for large format cutting lines, and ensuring high performance and shorter cycle times to meet the needs of medium and large industries. The Terma thermoforming machine by Fraccaro, on the other hand, is the ideal solution for thermoforming plastics using a vacuum mold.

The Selco Plast WN 7 is the top-of-the-range panel sizing machine designed for large format cutting lines, and ensuring high performance and shorter cycle times to meet the needs of medium and large industries. The Terma thermoforming machine by Fraccaro, on the other hand, is the ideal solution for thermoforming plastics using a vacuum mold.

Finally, the new Primus Plast water-jet cutting system has been conceived to meet the demand for maximum versatility, while Winstore is an automatic warehouse for optimized panel management in large companies working to order, able to ensure short production time and reduced costs.