Saipem tests a technology for the disposal and the reuse of unsorted heterogeneous plastic

Plastic recycling is the goal of Saipem’s latest technological solution. The company has in fact signed a licence agreement with Itea, an Italian company that owns the patent, for application of the technology in a variety of settings. Originally designed for applications in the oil & gas sector, the technology is particularly suited to solid urban waste disposal, in particular unsorted heterogeneous plastic, the so-called plasmix.

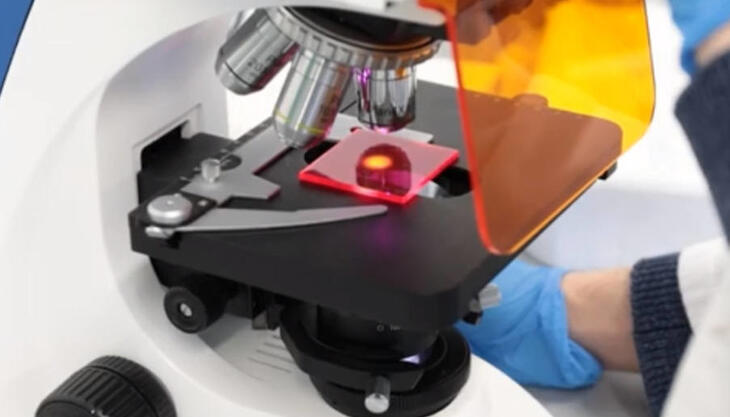

The new technology fine-tuned by Itea involves a particular process of plastic decomposition called “flameless oxy-combustion”. This produces water, energy and pure carbon dioxide, which is not emitted into the atmosphere, but which is ideal for use as a product destined for the market. Furthermore, the process is very flexible, relatively simple and can be exploited even in small-sized facilities. It is hoped that, in the future, it will lead to a noteworthy increase in the percentage of recyclable material in a sustainable way. Another advantage of the technology is that it affords the possibility to process plasmix along with sewage sludge deriving from the treatment of wastewater, a material which at present is difficult to dispose of.

Plastic recycling is an objective of great interest to Saipem, although further studies and technologies are required. However, we do not want to remain immobile while our seas and soils are being polluted by plastic. The widespread application of the oxy-combustion process could facilitate recovery of the precious energy content of waste plastics while avoiding their dispersion. Use of this technology confirms our ability to adapt oil&gas technologies to new market demands and to support our clients by providing them with solutions targeted at achieving greater sustainability”, Mauro Piasere, COO of Saipem’s XSight division, stated.