From post-consumer PET bottles directly to rPET food packaging

Recently, the strategic partnership between Amut and Erema has led to the installation and commissioning at the Alto Plastic Packaging site in Albany, New Zealand, of an extrusion line to process 100% washed post-consumer flakes into food-grade PET sheets. This is the first line ever installed in New Zealand for this special application. Alto Plastic Packaging is a division of the Pact Group and this investment is part of the group´s vision to contribute to circular economy in the country.

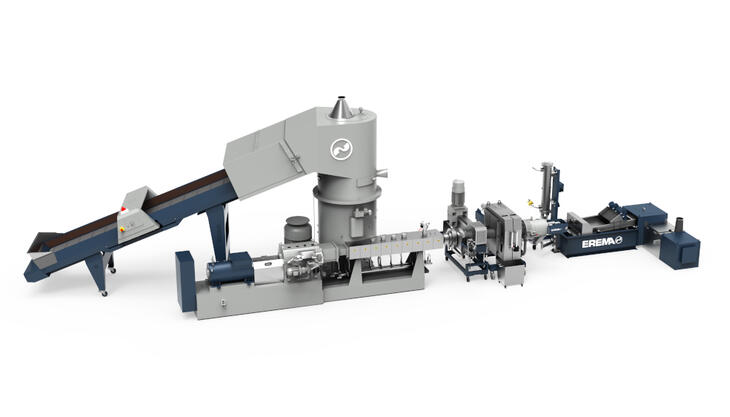

Thanks to the direct combination of Erema’s Vacurema PET recycling technology and the AMUT inline sheet production technology, there is no longer any extra process stage. This is because the melt goes straight from the Vacurema 1716 T Basic, where the post-consumer PET material is decontaminated and pre-dried prior to extrusion in the vacuum reactor, directly to the Amut plant without the detour of pelletising, reaching a throughput of up to 1,500 kg per hour.

After high-capacity filtration by means of the Erema SW-RTF backflush filter and online IV measurement, the melt goes directly into the Amut plant where it is processed into thermoforming sheet from 0.15 mm to 1.2 mm thickness. The monolayer thermoforming sheet produced from 100 % pure rPET is food contact compliant. At Alto Plastic Packaging it is further processed into trays and food containers.

Amut played its part by providing a full range of downstream equipment ranging from the Automatic Tdie, a three-roll stack calender with automatic gap control and motorized cross axing unit, lamination unit, thickness control gauge to anti-static silicon coating unit, fully automatic two shafts turret winder and in line edge trims grinding and recycling. The complete automatic and easy management of the line is made possible thanks to the new Amut`s software including the Easy Start and Easy Change functions that allow the operator to start the extrusion line and change product formats in automatic mode.