STADECK: collaboration allows SABIC to build on STAMAX success

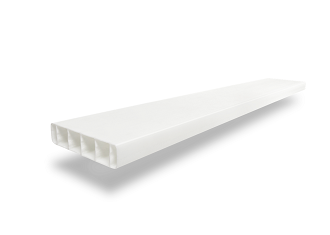

The construction industry still has enormous development potential. But a traditional approach to materials, especially in areas such as scaffolding and framing, means that bulky and not very sustainable options still dominate. In response to growing calls for ergonomic and environmentally-friendly solutions, SABIC has developed STADECKTM, a multi-wall structured panel made from SABIC’s STAMAX glass fiber reinforced thermoplastic resin.

The new solution came about following SABIC’s collaboration conversations with several influential companies specialized in scaffolding and frame working. From these discussions, we learned about several aspects of traditional materials used in scaffolding panels that the market had concerns about, including lifespan, ergonomics, and sustainability.

STADECK panels are extremely lightweight and offer significant benefits across a wide range of construction applications and building techniques where weight reduction, safe handling and a long lifespan are essential. Additionally, the panels have superior weather and chemical resistance, anti-slip properties, and excellent fire behavior.

Looking closer at its lightweight properties, it is clear that this new solution delivers benefits. STADECK weighing 8.5 kg per sqm, clearly outperforms each alternative material used in scaffolding panels, including pinewood (weighing 14.7 kg per sqm for 32 mm gauge and 23 kg per sqm for 50 mm gauge) steel scaffold panels at 22.6 kg per sqm and aluminum scaffold panels at 13.8 kg per sqm.

From a health and safety perspective, STADECK panels have better ergonomics and can be designed to enable more comfortable handling by construction workers and to prevent hand injuries. Reduced weight also improves logistics as transportation burdens are lessened. And when it comes to the final scaffolding structures themselves, the total weight is less.

From a health and safety perspective, STADECK panels have better ergonomics and can be designed to enable more comfortable handling by construction workers and to prevent hand injuries. Reduced weight also improves logistics as transportation burdens are lessened. And when it comes to the final scaffolding structures themselves, the total weight is less.

Another advantage of STADECK is that holes for assembly can be quickly drilled into this material without impacting mechanical strength. STADECK can be fixed using the same fittings as wooden or metal panels, and they can be cut in the same way as wood. From a design point of view, STADECK offers a multitude of possibilities beyond what wood can provide.

When compared to the standard wooden panels commonly used in the building industry, STADECK panels are a more sustainable option too. This is due to their excellent recyclability and weight savings, which can be as much as 60%. STADECK panels bring very substantial overall cost savings of up to 32%.

Last but not least is the durability advantage. STADECK panels have been extensively tested and initial feedback confirms the panels’ high performance with expectations of a 10-year lifetime provided they are appropriately handled. This far surpasses that of wooden alternatives, which may only last 18 months.

STADECK is made with SABIC STAMAX, a material platform consisting of long glass fibers (1.5 cm), a polypropylene matrix and additives, made by a patented wire coating process and supplied in the form of granules or pellets. STAMAX will be just one of the materials innovations that SABIC will highlight during K 2019 in Düsseldorf from (October 16-23, Hall 6, Stand D42). Under the theme of “Making a World of Difference Together”, SABIC will showcase its latest advanced solutions to help combat some of the world’s most urgent sustainability challenges.