Innovative and sustainable solutions for the surface finishing

Under the motto ‘Making every product unique’, Kurz provides insights into innovative plastic surface solutions at Fakuma 2021. The company presents itself as a “partner for future supplier challenges” with pioneering concepts, in particular in the areas of automotive interior/exterior, consumer electronics, and home appliances. In addition, the thin-film expert focuses on its comprehensive sustainability expertise.

Automotive: solutions and components for the mobility of the future

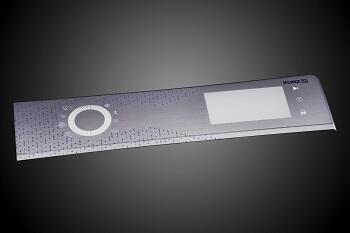

Tomorrow’s vehicle interiors increasingly do not require any mechanical switches or buttons. More and more, the technically complex control elements are hidden behind seamlessly sealed surfaces and are only activated by touch when needed. Kurz is considered an expert in automotive interior design and presents pioneering complete solutions from the HMI (Human Machine Interface) field. Thanks to the efficient IMD process (In-Mold Decoration) in combination with functional IML (In-Mold Labeling), decoration and sensor integration can be achieved in a single process step - and thus more cost-effectively than previous processes - all with a great deal of design freedom.

In order to give trade fair visitors an impression of the innovative power of Kurz and its subsidiaries, various demonstration samples are used. Kurz presents, among other things, an HMI concept panel, which only last year was honored with the Red Dot Award for outstanding product design. What’s more, the trade fair stand features a pioneering Overhead Console Concept, which the Kurz Group has developed in cooperation with its partner companies Osram, Syntec, and Wittmann Battenfeld. In addition to a patented series-ready in-mold electronics solution, the roof-lining console module also showcases expertise in Shy Tech design and ambient lighting with integrated logo projection. There are also live demonstrations with a Baier hybrid machine, which enables the subsequent customization of IMD-decorated components using digital printing. The live process at the fair shows the subsequent finishing of a 3D-shaped organic component - in the form of an automotive door trim. IMD Unify also enables the combination of backlighting and Shy Tech effects as well as the use of touch sensors in different integration variants, for example through functional foil bonding or functional in-mold labeling. The great advantage of the new process is the durability and the excellent adhesion of the digital printing inks used on the surface of the injection-molded part.

Indium as an innovative metallization option

The presentation of new designs and real metallizations is another highlight at Kurz’s trade fair presentation. In addition to chrome, aluminum, and tin, the company has recently also started offering indium as a promising option. The innovative metallization variant is similar in color to that of hard chrome, but at the same time is significantly more environmentally friendly and less harmful to health than the electroplating process. Another advantage is the radar and 5G permeability of indium, which makes this metallization option interesting for many industries: for automotive manufacturers, this product feature is relevant for autonomous driving, for example when used on the exterior of modern front panels. The same applies to manufacturers of consumer electronics who want to serve the trend towards smart consumer products with antenna technology such as mobile phones, tablets, or loudspeakers, for example. In the household appliances sector, the indium-based metallization option also has great potential: for example, in the innovative panel design and highly functional control panels used in products for the smart home segment.

Automotive exterior: Kurz sets new standards for the vehicle of tomorrow

What future trends can be expected for automotive exterior design? Kurz is also addressing this question at Fakuma. The innovative front panel in a futuristic design, with which the company has set a milestone in the development of the vehicle of tomorrow and received the ABC Award 2020, is certainly particularly eye-catching. The pioneering “Iconic Space Grille” was manufactured using the particularly efficient IMD Decopur process and meets all the requirements of the mobility of tomorrow. A closed, robust, and self-healing polyurethane surface was created for the front of the vehicle, which, on the one hand, projects the brand by means of logo integration and, on the other hand, enables visual communication of the vehicle with the environment thanks to modern and customizable LED technology backlighting effects. In terms of design, the Iconic Space Grille boasts the entire range of design options for the car of tomorrow: From three-dimensional depth effects to metallization or coloring of the polyurethane layer, the design options are virtually boundless. Kurz has joined forces with its partner company Sumitomo (SHI) Demag to present another highlight for the automotive exterior design of the future. At that machine manufacturer’s stand, for example, a live production area shows how a designer logo badge for the vehicle front is created using the highly efficient “IMD second surface” process, with contactless subsequent cleaning of the component.

Home appliances: series production with highly efficient customization

Home appliances: series production with highly efficient customization

Visitors interested in the home appliances segment can also see the aforementioned IMD Unify customization concept first-hand. In live demonstrations, an IMD-decorated washing machine panel is subsequently customized with digital printing. The particular advantages of this process are superb flexibility and cost efficiency in the manufacturing process. The production of special models or regional variants is thus possible without additional production effort and without further transport routes. This means that a wide range of customizations can be implemented for a basic design, depending on market requirements.

Consumer electronics: pioneering product design

Possibilities for antibacterial surface finishes are gaining in importance - particularly in the context of the Covid-19 pandemic. The consumer electronics sector, in particular, comprises many products that are exposed to frequent contact - such as notebooks, smartphones, or light switches. The same applies to the vehicle interior. Innovative concepts are required here to eliminate bacteria on surfaces. Kurz’s answer is the IMD Biofense process, first presented last year. This innovation has been added as an option to the tried and tested In-Mold Decoration process, which can ensure an invisible antibacterial effect with a long-term result on plastic surfaces.

Life Cycle Thinking

Climate change is considered a major challenge of our time. In addition to environmentally friendly production that is as CO2 neutral as possible, energy efficiency has also become a core business task. Kurz meets these requirements with a comprehensive sustainability concept that makes saving resources and improving the life cycle assessment an important aspect of corporate management. With its Life Cycle Thinking approach, the company is committed to a holistic recycling cycle. On the one hand, it ensures the recyclability of decorated components, and, on the other hand, it has created Recopound, a solution for producing high-quality recycled pellets from production residues. Recopound is in no way inferior to new material in terms of the wide range of decoration options, can be processed on conventional production machines and is particularly durable and robust thanks to optimized mechanical properties. The biggest advantage, however, is environmental protection. By using the recycled material, up to 40% CO2 can be saved compared to new material. At Fakuma, it becomes clear how versatile and visually appealing Recopound products are. At the stand of Kurz partner Deckerform, watering cans and flowerpots are made from the recycled material and handed out to trade fair visitors as giveaways.