Polyurethane is cool!

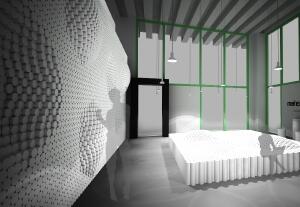

On Wednesday, 12 September, Pelma, an important producer of flexible polyurethane foam, presented an innovative and revolutionary material to the public and to the press that offers optimum temperature and humidity control: Thermofresh, a name that evokes its cooling power. The presentation took place during an open day at the Milan Triennale at the Material Connection Space, where a number of installations made of PU foam will remain on display until 30 September.

The outcome of a long research project in nanotechnology, conducted in collaboration with the Industrial and Materials Chemistry Department of the University of Bologna, this polyurethane will be used principally to produce mattresses and pillows, where scientific tests have demonstrated its capacity to reduce contact heating. And precisely for its characteristic as a "cooling material", Thermofresh will find application in other areas as well, ranging from padding for knee and elbow guards in sports and motorcycle helmets to baby-care accessories such as crib padding and cradles.

Thermofresh is made using a special process known as the Controlled Predispersion System, which makes it possible to introduce Phase Change Materials (PCM) and distribute them uniformly through the formulation. The PCMs are micro-capsules initially developed by NASA and are able to absorb heat and maintain a near constant temperature inside the material.

Thermofresh polyurethane is also distinguished for its antibacterial properties thanks to the presence of silver salts, which prevent the proliferation of mould while ensuring eco-compatibility, since it is made without the use of environmentally hazardous substances such as methylene chloride.