Highly functional and ecological packaging

Under their motto "Welcome to the Global Collaboratory" DuPont will showcase at Interpack (Düsseldorf, May 8-14, 2014), how interdisciplinary cooperation with customers and other market-leading players can open up a multiple of possibilities for increasing the functionality and attractiveness of plastic packaging materials and components, while at the same time reducing both the industry's ecological footprint and the unnecessary waste of food. In particular, DuPont and Reifenhäuser Kiefel Extrusion have collaborated to bring two innovative high barrier packaging solutions to market, optimizing Evolution barrier blown film lines to suit the processing parameters:

- A new APET based DuPont Appeel high-performance sealant resin is used for the production of PA-based lidding films, which combine a high barrier effect with good printability. They seal directly and safely to trays of 100% APET, obviating the need for APET/LDPE tray laminates. Thus both material costs as well as lid and tray production costs can decrease.

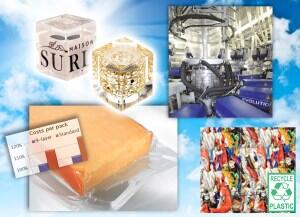

- A special grade of the DuPont Surlyn packaging polymer allows the production of thermoformable barrier films that can be made 20% thinner than conventional 7-layer PA/PE films, accompanied by lower costs, improved optical properties, higher puncture resistance, excellent abrasion resistance, and improved sealing properties.

Together with Kuhne Anlagenbau, DuPont have developed a project to extend the field of application of the TripleBubble process for the production of biaxially stretched films. With up to eleven layers of functional plastics, Surlyn Ionomers and Bynel adhesive resins, these films are available in thicknesses of 20 up to 110 microns. All grades combine high, adjustable shrinkage from zero up to 60% and a very high barrier against oxygen and moisture with outstanding transparency, high gloss and - despite the comparatively low thickness - very high ear strength and puncture resistance. This allows significant savings of raw materials (up to 50%, depending on the application) and energy, and consequently much improved results in the life-cycle analysis.

New Entira EP compatibilizers lower the barriers for the material recycling of packaging. Even additions of only small quantities of around 4% to the regrind of inherently incompatible packaging polymers make for a more economical and efficient recompounding process. Consequently the tensile strength, elongation at break and, in particular, the impact strength of the recyclate are increased to a level that meets the demands for high-performance applications. Grades optimized for specific applications are currently at the development stage.

In close co-operation with Braskem, DuPont is developing renewably sourced tie-resins and polymer modifiers to extend the existing range of the Bynel and Fusabond resins. For this purpose, DuPont will use Braskem's renewably sourced polyethylene (PE) to produce drop-in alternatives which either meet or exceed the performance of the company's conventional petroleum based products and are fully recyclable in PE waste-streams. Target applications for renewably sourced grades of Fusabond include applications like wood/plastic composites, starch/PE compounds and glassfibre/PE compounds where use of a renewably sourced modifier significantly increases the renewable material percentage in the structures.

The Surlyn 3D textile overmoulding technology opens up new possibilities for applications in the cosmetics and design sector as the result of a cooperation between DuPont and Oriol & Fontanel, France. Here, the partners have succeeded in overmoulding intricate textile articles such as lace or woven ribbons with the Surlyn packaging resin, and thus embed them into three-dimensional objects. It is possible in this way to protect the delicate objects without them becoming damaged or altered during the process.

Last but not least, the company's constant commitment to the smart use of packaging to support the better use of foodstuffs is underscored by two presentations by DuPont team members at the exhibition accompanying the Save Food Symposium.