Reduced variation in individual layer thickness

A Nordson EDI nine-manifold flat die, the first of its kind, has been successfully commissioned, producing nine-layer film from various resins. While the degree of improvement will vary with the application, in general Nordson EDI’s nine-manifold die technology promises to reduce variation in individual layer thickness from the ±15% tolerance often encountered with comparably advanced feedblock systems to ±5%, according to Sam G. Iuliano, chief technologist for Nordson EDI. “This greater accuracy achievable with multi-manifold dies enables processors to run thinner layers of the costly specialty materials often required for high-performance packaging films, while at the same time enhancing product quality and consistency,” said Iuliano.

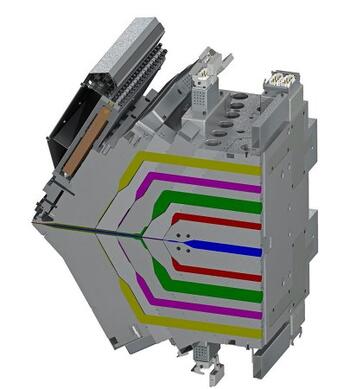

A manifold is a flow distribution channel inside the die whose complex internal geometry, engineered for a specific polymer, is designed to develop a uniform, streamlined flow and distribute the material to its full width. In a multi-manifold die, each polymer flow stream has its own manifold, and the layers are combined into a single structure only after each layer has been individually spread to its full width. By comparison, a feedblock combines multiple polymer streams into a narrow multi-layer “sandwich” that is subsequently distributed to full width in a single-manifold die. A chief reason why the multi-manifold method provides greater layer uniformity and thickness accuracy is that it avoids much of the layer-interface deformation that occurs when multiple layers pre-assembled in a feedblock are then spread simultaneously through the die.

“Nordson EDI customers around the world have long benefitted from multi-manifold coextrusion, using dies with two, three, four, or five manifolds”, noted Iuliano. “Engineering a nine-manifold die was a big challenge for us, since ten major die body segments had to be adequately fastened and heated. In addition, the nine flow channels were each custom designed for the specific layer that they were distributing, meaning that we had to accommodate flow channels of varying sizes and layouts in the design”.