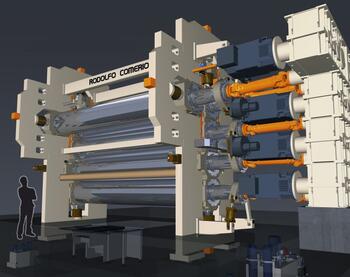

Giant calenders on top of the world

Rodolfo Comerio has developed two enormous calenders, among the largest ever built worldwide, for the lamination of thermoplastic resins and bonding with special materials. One features 4 and the other 5 cylinders (each with a diameter of 870 mm) and they both have a 5,000 mm working table. Each of these 30-ton calenders is over 8 m long (pins included) and weighs 30 tons. These calenders will be capable of producing materials with a thickness of less than 80 microns; around 60 containers will be needed to ship them.

According to a statement released by the company, the customer’s declaration that Rodolfo Comerio was the only manufacturer able to build these two giant lines was a source of great pride for the company’s two owners, Enrico and Carlo Comerio. Strengthened by the orders received in 2015, the ones already won in the early part of 2016, and this considerable order, the manufacturer has recently taken on new staff and started the construction of a new plant, which will complement the existing one.

In the meantime, the research and development

department is completing its development of a new technology for the calendering

of rubber (for the production of tyres and various other applications) and PVC.

At present, no further information on this new development is available, but

the company, on the strength of the positive results obtained with the first

tests, which far exceeded expectations, expects it to be a revolution in the

field of calendering.

These are the most recent chapters in the story of Rodolfo Comerio, a company that started out in 1878 in Busto Arsizio, in the Italian province of Varese. At the time, the town of Varese was regarded as the European capital of the textile industry and, in fact, Rodolfo Comerio, the founder of the company, started his business designing and building machines for the processing of textile fibres. In the early years of the twentieth century, his son, Enrico, extended the production range to machine tools (for the national arms industry), flanking the machine shop with an innovative foundry for large cast iron work.

At the start of the 1920s, Enrico’s son, Rodolfo, had the brilliant idea of steering the company in a new direction, namely, the construction of machines for the processing of rubber and thermoplastic resins (PVC), and produced the company’s first roll calenders, designed precisely for these flourishing sectors. The first customers of that period included Pirelli, as from 1925, and the Montecatini group, as from 1942.

In the 1960s, Rodolfo’s sons, Enrico and Carlo, who

are the current owners, firmly set their sights on increasing productivity,

implementing constant technological upgrading and strengthening the company’s leading

position. In 1981, the business moved to the new Solbiate Olona facilities,

still in the province of Varese. Located just a few kilometres from Milan’s Malpensa

international airport, this modern plant covers over 35,000 square metres. Over

the following years, the company’s innovative drive was reflected in a wide

range of products, which were increasingly exported worldwide; today, exports

generate 90% of the company’s turnover.

Rodolfo Comerio is today one of the oldest companies in the world specialising in the design and construction of plants for the production and lamination of plastic sheets. Since 2008 it has almost tripled its annual turnover and has also increased its number of employees. 2008 was, of course, the year that saw the explosion of the global economic crisis, but the company succeeded in overcoming that difficult period through its capacity for renewal, study of new technologies, and lodging of important patents in the field of machines for the production of embossed plastics matched with the underlying prints. In 2012, the company began to work on plants for the processing of rubber destined for uses other than tyres, immediately receiving important feedback in the field of rubber-coated fabrics for offset printing and conveyor belts. Much of this success can be attributed to the professionalism and creativity of the managing director Carlo Comerio, who, with great enthusiasm and commitment, likes to work side by side with his staff, analysing every single request received by the company, studying machinery capable of improving production processes, and ensuring that the needs of converters are met.