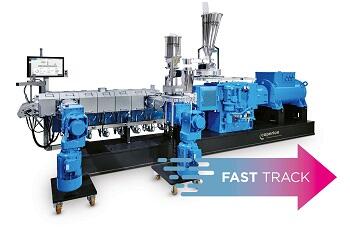

Coperion provides two new Fast Track ZSK extruders to Sirmax

Italian compounder Sirmax goes forward to invest in technological innovation, continuing strongly in the direction of a sustainable business. The company from Padua (Italy) has expanded its production capacity for sustainable plastics, relying upon Fast Track ZSK extruders from Coperion. These new models stand out for their especially short lead times and subsequent rapid ROI. In Sirmax’s case, Coperion designed two ZSK 70 Mc18 twin screw extruders especially for processing bioplastics. Only five months after placing the order, both Fast Track ZSK extruders have commenced production.

Sirmax installed the ZSK 70 Mc18 extruders, each with 70 mm screw diameters, ZS-B side feeders and ZS-EG side devolatilization, at Microtec Srl’s Padova (Italy) location. Sirmax has held a 70% interest in Microtec for the past year, a manufacturer of biocompounds marketing its products under the name BioComp.

With its Fast Track initiative, encompassing comprehensive internal and external process modifications, Coperion can now realize certain designs of its ZSK twin screw extruders with especially short lead times. Just as they have always been, these extruders are built exclusively with proven, high-quality components, including the high-performance drive and high-quality materials for the process section that ZSK extruders are famous for, to name just a couple of examples. Moreover, Coperion’s entire process engineering expertise flows into the Fast Track twin screw extruders. Each process step is designed individually and optimally, all coordinated for the application in question, which in the case of Sirmax’s extruders is bioplastics processing.

Comprehensive modifications at Coperion, such as in warehousing, as well as numerous measures at suppliers’ locations, enable turnaround of ZSK Fast Track extruder orders with lead times of only five months. Compounders profit from expected high throughput rates and rapid ROI. Additionally, using exclusively high-quality, proven components provides the same service life as well as high process stability with constant very good product characteristics that distinguish all ZSK twin screw extruders.

Microtec will manufacture compounds based on starch biopolymers, co-polyesters (PBAT), polylactic acids (PLA), and polybutylene succinate (PBS) on the two Coperion Fast Track ZSK 70 Mc18 extruders. These bio-based materials are mainly used in the blow molding and in the injection molding market.