Colines expands ALLrollEX 1500 plant configurations

ALLrollEX 1500 turns 12 and after more than 250 installations worldwide, making it one of the most popular solutions for 1.5 m wide stretch film extrusion, Colines is expanding the available configurations to increase ease of use, flexibility of application, production of specialty films and waste reduction. All this without compromising their high technological standards, production yields and quality.

New features include:

- extruders platform for 5-layer, 7- layer and nanolayer film structures;

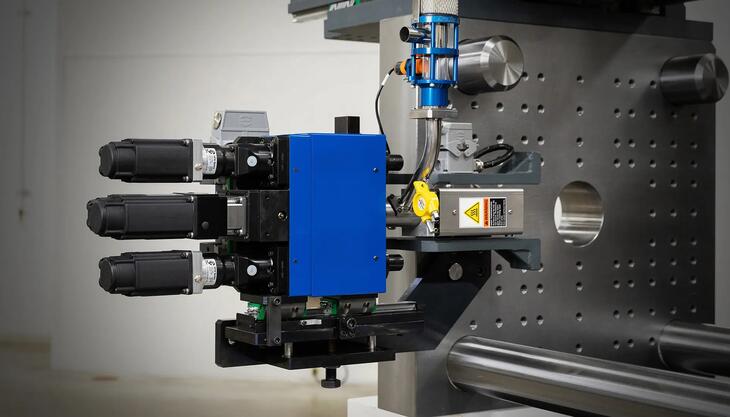

- Mastermind virtual production assistant (Artificial Intelligence allowing touchless extrusion die adjustments, process stability control, rolls width change without halting the machine etc.);

- processability of PCR (Post Consumer Recycled) materials;

- enhanced Big Mouth inline edge trim recovery system;

- ALLspeedy IV winder able to run inline 2-, 3- and 4.5-inch cores (the last specifically designed for food wrap cling film) and reels of diameter up to 800 mm suitable for converting;

- inline coreless reels and pre-stretch film production of improved quality even at high speeds by means of the patented NoEl system;

- inline oscillating and folding system for reinforced edge rolls;

- Live Control MES for manufacturing process optimization through advanced data analysis algorithm.

ALLrollEX plant keeps being available through the “Quick Delivery Program” which grants the shortest delivery time.