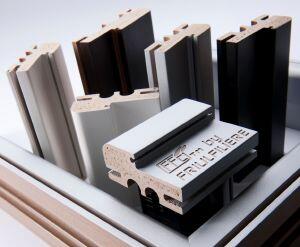

Composite foam

FFC (Foam Fiber Composite) technology has been developed by Friul Filiere (located near Udine, Italy)for the production of profiles in PVC-wood fibre composite. This closed-cell foam material is lighter and cheaper than the WPCs (Wood-Plastic Composites) available for similar applications. It is thus possible to use 50-75% PVC by weight, obtaining a finished product with an inner microcellular foam with specific weight as low as 0.6-0.7 g/cm3.

The compound is homogeneous, recyclable, self-extinguishing, dimensionally stable and suitable for processing by single-screw or twin-screw extruders without granulation. For the production of finished profiles directly from dryblend, the company offers an Omega single-screw extruder with degassing, volumetric metering and screw for loading and plasticizing materials with low bulk density.