Injection + blow moulding

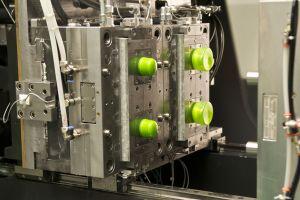

The acronym IBMP (Injection Blow Moulding Process) identifies the new technology for producing containers of different capacities and shapes in a single injection + blow-moulding process developed by Cantoni, working in conjunction with Engel. This process was demonstrated at PLAST 2012 on a Victory 330/90 Tech press making small containers in PP with a two-cavity mould and a cycle time of 14 seconds.

The system can handle various numbers of cavities and the production output is particularly high thanks to the possibility of overlapping the injection and blow-moulding operations. It is based on a single-block mould with excellent heat distribution, something which is particularly important in creating perfectly balanced containers without seam lines or flash. The mould uses a central injection station and two lateral blow-moulding stations. The cycle is as follows: moulding of the first series of pre-forms, opening and moving of the mould to the side for the blow moulding of the first series, simultaneous moulding of the second series of pre-forms and associated blow moulding.