Two layers instead of three: the barrier remains the same

NatureWorks and Metalvuoto announced a new generation of high barrier Ingeo based flexible substrates designed to keep processed foods fresh on store shelves. While Ingeo film has been used for years in fresh food packaging, this is the first application for longer shelf life foods that are increasingly packaged in flat, stand up, or squared bottom pouches.

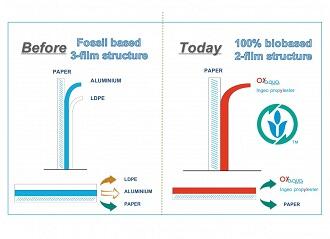

The introduction comes in response to a strong interest from the flexible packaging market in packaging simplification, with brands looking to move from complex multilayer laminates to simpler packaging solutions without compromising shelf life. The Metalvuoto film allows using a two-layer pouch with performance matching that of three-layer pouches.

Gianni Costanzo, Metalvuoto executive director, explained, "Until now, the flexible packaging industry has grown up around the use of multi-material laminates because no one material was able to provide multiple functionality. For example, brand owners often use an aluminum layer for barrier, a PET layer for external aesthetics, and an internal PE layer for heat-seal ability. Now, we have used the Metalvuoto Oxaqua coating technology with an Ingeo base film to replace two layers of different materials with one layer that simultaneously provides excellent barrier and heat-seal ability”.

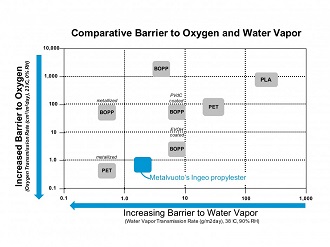

The new

film, which Metalvuoto terms Ingeo Propylester, has barrier properties of less

than 0.75 cc/m2/24hr for oxygen and 2.5 g/m2/24hr for

water vapor. This provides a significantly better oxygen barrier than

metallized biaxially oriented polypropylene (BOPP). Barrier performance is

compared in the figure below against a range of materials normally considered

for use in flexible packaging markets.

The new

film, which Metalvuoto terms Ingeo Propylester, has barrier properties of less

than 0.75 cc/m2/24hr for oxygen and 2.5 g/m2/24hr for

water vapor. This provides a significantly better oxygen barrier than

metallized biaxially oriented polypropylene (BOPP). Barrier performance is

compared in the figure below against a range of materials normally considered

for use in flexible packaging markets.

Metalvuoto's Ingeo based film provides good seal strength (>80 g/cm2), eliminating the need for an additional sealant layer and enabling a structural package simplification. Costanzo said that Metalvuoto expects strong interest from the market in two-layer structures in which the Ingeo and Oxaqua biocoating technology are combined with paper to provide a fully biobased performance package at a cost competitive with current three-layer structures.

Ingeo Propylester is well suited for food packaging in both horizontal and vertical form-fill-seal applications, and has demonstrated good process ability. In testing on pouch making machines, 30 to 40 units per minute were produced, depending on the type of Forest Stewardship Council (FSC) certified paper pouch-flat, stand up, or square bottom.

Metalvuoto gave a presentation on the new possibilities this technology offers for the pouch market at Innovation Takes Root, the global Ingeo users' forum, March 30-April 1 in Orlando, Florida.