11 million cycles without maintenance

XForm 500 preform injection moulding system by Sipa is getting another upgrade. The 500-ton system is already into its third generation since it was introduced at NPE 2012 just six years ago. It stands out for its speed, its versatility (it accepts any generation of legacy tooling from any major mould maker), its energy efficiency - consumption is under 220 W for every kilo of PET consumed - and its reliability.

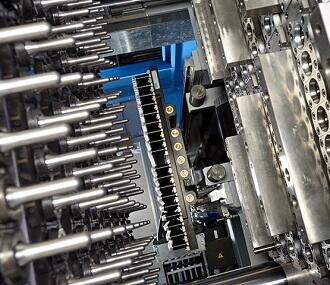

Now, a new feature on the mould cold half lets XForm 500 stay out even longer between pit-stops.

Untill today, GEN3 third-generation cold halves were guaranteed to run for eight million cycles before maintenance was recommended to ensure that there was never any flash over 0.2 mm. Sipa can make this guarantee, thanks to the use of its LongLife surface treatment and a strong mould structure with very low deformation, high precision and high reliability - as well as optimized cooling.

Eight million maintenance-free cycles is a lot. But now Sipa is going well beyond this. It is extending the guarantee period by close to 40% - to 11 million cycles. More time saving, more money saving, more satisfaction all round.

The XForm 500 is capable of running with preform moulds holding up to 180 cavities. This means that between one refurbishment and the next, the system can produce almost two billion preforms. That’s a lot of bottle.