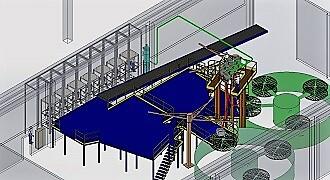

Gravimetric dosing and thrust transport

Thanks to the Rotodosing system - that ensures an ideal weight for each mould - combined with the Powderspeed system - used for the long distance transport of powder and non-powder materials - Dega offers a solution which can solve the problems concerning the costs due to the wastage of material during the production phase. The production cycle with the different weights for each mould is guaranteed by a dedicated software, which - supported in some cases by a barcode reader that identifies each mould and, in other cases, by a driver for the communication with the customer’s management software - quickens the cycle and avoids any typing mistakes of the operator.

The functioning is very simple. The barcode reader or a selection in the customer’s management software inform Dega system about the quantity to be dosed and the type of material to be transported (if the customer uses more than one.) After that the material, stocked in big bags or in dedicated containers, is extracted and transferred to a weighted storage container, placed in the area where the material is prepared.

When the material has reached the desired weight, it is transferred inside a container, placed above the mould area. A flexible pipe starts from there and it is used by the operator to reach all the moulds of the group.

The visual signals of the system inform the operator that the material was completely transferred and is ready to be loaded in the desired mould. At that point, the operator sends the impulse to the system, which opens the valve under the container to unload the right quantity of material in the mould. In the meantime, the system itself is already preparing the following throw (if present.)

For each mould, the management software allows to program not only the weight, but also the type or the colour of the material, and it is possible to program compounds of different materials to obtain special effects (for example ancient stone effect, wood effect, clay effect, etc..) The material can be transferred even along a significant distance (over 50 metres) without affecting its accuracy.