Advanced technology made in Comi Group

In Italy there exist companies that achieve high performances without making a lot of noise about it, basing their results on expertise gained through years of work and continuous advancements. This is a category that includes the Comi Group, which comprises five companies - Comi, TechMill, Comi Effelle, Parco and Amut Comi - and operates in numerous, mutually complementary sectors of the manufacturing industry, such as on-line thermoforming machines for packaging, five-axis milling machining centres, presses for composite materials, rubber and thermosets, and moulds for thermoforming and punching. The Comi Group operates through four sites: Ciserano (Bergamo), Levate (Bergamo), Vigevano (Pavia) and Cairate (Varese).

The founding company of the group is Comi, based in Ciserano, which is active worldwide in the field of plants for thermoforming and whose turnover in 2014 saw an increase of 87% on that of the previous year. The share of this turnover generated by exports was greater than 80%, with the company exporting to over 50 countries the world over. TechMill produces five-axis machining centres for the processing of composite materials and light alloys. The natural fields of application for these machining centres, whose design features innovative engineering and systems solutions, are those of technical composites and light alloys, particularly for the aerospace industry. An important synergy with the Amut Group has recently been established through the creation of a joint-venture: Amut Comi is active in the field of thermoforming machines for food and non-food packaging. To ensure adequate support for the company, given its increasingly complex organisation and its efforts to internationalise production and sales through foreign subsidiaries and to improve quality standards and after-sales services, the management of the Comi Group was recently entrusted to Silvio Tavecchia, who has previously held leading positions in companies such as Terenzio, BM Biraghi, Negri Bossi and Sytrama.

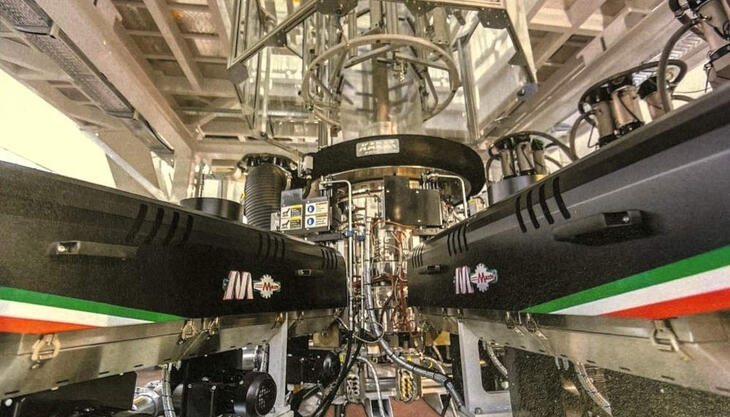

At Plast 2015 the Comi Group (stand B 71/C 72, hall 13) is exhibiting four solutions: a LaborForma single-station thermoforming machine with automatic reduction frame, quatz resistance and male half-mould; a LaborMax five-axis machining centre, one of the most versatile and configurable in the range, suitable for milling plastic and composite materials and aluminum; a Labortech 50 vertical, two-platen laboratory press, available with active parallelism control, a vacuum chamber and magnetic heating platens; and an AMP 850 thermoforming machine featuring a tilting platen and pressure thermoforming.